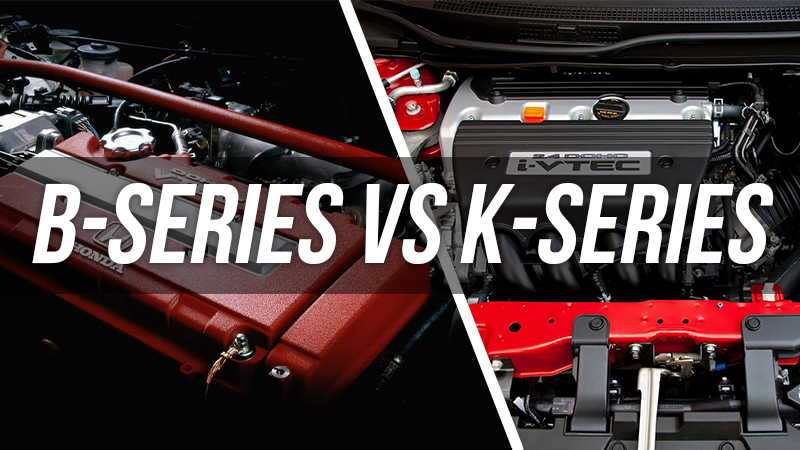

The Honda B and K series engines are the subject of a fierce, ongoing internet forum war; some fought like religious wars between fans of different denominations. These loyalists will not hesitate to unleash their anger on anyone who dares disagree with them – including personal attacks or flat-out flaming.

But when you look at each one objectively and remove all bias, there aren’t as many pros for one over another: they’re just different strokes for different folks.

The Honda B and K series engines are. They have passionate supporters, but when you get into the nitty-gritty of why people choose one machine over another – there’s not all that much difference.

However, the most apparent pro for each type is its versatility: it can be tuned to suit any need or riding style with ease thanks to many reasonable modifications available from shops specializing in these types – for instance, an intake system. On top of the equalized performance abilities across RPM range–which also makes them better choices during acceleration runs -both provide strong torque at lower RPMs.

What are Honda B-series Engines?

To begin, the B20A engine was originally debuted in Japan in the 1986–1987 Prelude 2.0Si and the 1986–1989 Honda Vigor and Accord. While several distinct varieties of the B20A emerged in the Honda Prelude from 1987 to 1991, the engine’s foundation was substantially different than the popular B16/B17/B18 series.

However, the B16/B18 family shares many popular B-Series parts – both OEM and aftermarket. In addition, the B20B and B20Z were reintroduced by Honda in the first-generation Honda CR-V. This iteration of the B20B and B20Z was supposed to be more like the B16/B18 family and the B20 VTEC engine developed by enthusiasts. The B20B and B20Z shared characteristics with the well-known B16/B18 family.

Because of its dependability and ability to produce high horsepower compared to displacement, Honda’s B-Series engines have become the most prized Honda engines. They are also easily accessible and moderately priced. The B-Series engine’s main advantage is its flexibility to be transferred into multiple Honda chassis, such as the Honda Civic.

Understanding the B-Series

Honda’s B series was a class of inline four-cylinder DOHC performance engines first launched in 1988. Honda’s VTEC technology was used for the first time in the B-series engines. They were available in 1.6L, 1.7L, 1.8L, and 2.0L capacities.

Later versions contain modest changes such as modified intake valves, ports, piston tops, and separate cylinder oil injectors. They produce between 126 and 190 horsepower, with certain types capable of exceeding 8,500 rpm.

Despite its various modifications, the core design of the B series is relatively similar. Two brief blocks are utilized throughout the series.

The cylinder block deck height was the difference among them. The deck height of the short block used for B16 and B17 engines is 8.03 inches, whereas the deck height of the short block used for B16B, B18, and B20 engines is 8.30 inches.

Over the years, the Honda B-series has had distinct engines. In Civic, Integra, and CR-V applications, the Honda B series was superseded by the K series.

The majority of the B series engines are turbo applications and are used in a number of street and drag vehicles. Circuit track applications can be performed with B series engines, but the majority of them are performed with K series engines.

Further, in factory form, B series engines can vary from 500 to 1,300 horsepower when fully constructed. Above that, things get out of hand. With a turbo, most individuals can get anywhere from 900-1,300 horsepower on a regular basis.

Understanding the K-Series

The Honda K-series engine, which was debuted in 2001, is a four-cylinder, four-stroke engine that superseded the B series. The K-series engines use DOHC valvetrains and roller rockers to minimize friction.

The engines have a coil-on-plug, distributor-less ignition system, with one coil for each spark plug. This system replaces the traditional distributor-based ignition timing system with a computer-controlled system that allows the ECU to manage ignition timing depending on multiple sensor inputs. The cylinders, like the B series engines, feature cast iron sleeves.

The K-series engines, like the B series, feature two short blocks with the same design. The main difference between them is the deck height – the K20 has an 8.3 inches deck height while the K24 has a 9.1 inches deck height.

On K-series engines, there are two variants of the Honda VTEC system, both of which can have variable timing control (VTC) on the intake cam. The VTEC system on engines such as the K20A3 only operates on the intake cam – at low rpm, only one intake valve is fully opened, with the other opening slightly to generate a swirl effect in the combustion chamber for increased fuel atomization.

Both intake valves are completely open at high rpm to facilitate engine ventilation. The VTEC technology acts on both the intake and exhaust valves of engines like the K20A2 featured in the Acura RSX Type-S, allowing both to benefit from numerous cam profiles.

To be honest, the K series engines are pretty reliable. The changes required for high horsepower on this chassis are identical to those needed for the B series – rods and pistons.

Their sleeves are a little thicker, so they’re a little stronger sleeve-wise. The valvetrain has to be improved as well because some of the equipment is being pushed to 10,000-11,000 RPM. They were never intended to retain that stock; therefore, one of the first things you should do is upgrade the valvetrain.

Streetwise, many street folks typically aim for 500 horsepower, which is quite simple. They’re built similarly to the B series, and folks are generating anything from 900-1,400 horsepower. It appears that the street number that everyone wants to go for is that mythical 500 horsepower.

Value For Money

The first thing that must be considered is money. Few car enthusiasts have access to a money tree or the unlimited financial resources to pour money at a project. As a result, the B series is a cost-effective option.

While racing versions often exceed 1,000 horsepower and street modifications creep up on unsuspecting V8s, the B is still a baby in the perspective of the aftermarket.

The B series shines if cost is a primary consideration in a planned development. And, because of a 12-year production cycle, there are plenty of B-series cores for sale in your area of choice. Most instances, particularly the B16s and B18A series, maybe have for a few hundred dollars, but rarer trims, such as the B18Cs and B18C5s, still attract top dollar.

But, it would be a lie to argue that the K-series isn’t expensive to construct or that it doesn’t have its fair share of aftermarket support. While swap kits for K engines are available, like those supplied by Hybrid Racing for ’92-’00 Civics and ’94-’01 Integras, they are an additional expenditure.

Retrofitting a K engine is unquestionably more involved than utilizing a B series engine, which was standard on much earlier Honda chassis in either USDM or JDM incarnations.

Size and Displacement

Nothing beats a greater displacement said primarily by engine aficionados and everyone else familiar with the mechanics of these engines. And, in the world of naturally aspirated power, this statement is especially true. As a result, the K series engines have a significant advantage over the Bs.

The smallest form of the K20 series, with a square, 86mm x 86mm bore and stroke as given by Honda, nevertheless has a 2-.4 liter advantage on the whole B-series range, save for the B20. Considerably the lesser K is enormous in the world of Honda four-cylinders, but they become even bigger.

When you add a K24 bottom end – an 87mm bore x 99mm stroke- the B-series cannot compete with the K’s displacement.

On top of that, the cylinder heads of the K-series performance engines are among the greatest the business has ever designed. With exceptionally high-flow ports, 33mm intake valves (2mm larger than the B series), and full-roller valvetrains, there’s no lack of atmosphere.

The K series is superior: the head has greater CFMs, roller rockers, and a larger displacement.

Boost and Reliability

The gap between the K-series and the B-series is closing in the field of forced induction.

While the K-series has the previously noted higher-flowing cylinder head and displacement increase, the B easily outperforms them with boost.

B and K engines can withstand a lot of abuse before they fail. Still, they will both require sleeving, upgraded fasteners, pistons, and connecting rods if exceptionally great boost and power numbers are your intentions for the engine.

Having said that, there is some disagreement among elite Honda builders over the horsepower limits of each of these engines in standard form.

The stock sleeves should be changed when nearing 300 horsepower on B series engines. While some enthusiasts claim to see engines exceed this number without sleeving, their experience says they are standing on the edge of the cliff.

While both the B and K blocks are factory-produced with cast iron sleeves, the K has extra aluminum cast surrounding the can, which helps with cylinder strength.

They can both tolerate a good amount of cylinder pressure. Still, we find a concern when either detonation is present or a power adder is employed, which pushes it above its limit.

Internals

Both engines come with cast slugs for pistons, but any experienced builder will advocate a forging in a turbo system. It’s tough to determine which of these engines has the most significant advantage when it comes to turbocharging, but the B series can certainly hold its own.

A larger K-series motor will spool the turbo a little faster; that’s a fact for sure. But, a lot of the faster turbo vehicles still use B-series motors.

Another significant benefit is in combustion chamber sealing, which the B-series engines excel at. The thing is that the sealing strength on the B series cylinder heads is a benefit for substantially boosted applications owing to the smaller bore and spacing, which allows for tighter head bolt position relative to the cylinder.

Valvetrain

Both the B- and K-series engines have extensively over-engineered blocks that can handle far more horsepower than Honda ever planned. The K-series is obviously the more inventive and refined platform when viewed side by side.

It is also ten years younger and the inevitable progression of the B-series engine. The inclusion of a timing chain is the first item on the “what’s changed” list.

Honda tuners have had a long time to grow acquainted with timing belts since Honda utilized them almost universally until the introduction of the F20c engine in the Honda S2000. Soon later, the K-series was launched, complete with — you guessed it — a timing chain.

Timing belts might give off a cool, sleek look, but there’s nothing like the timing chain when you need dependability and longevity. It puts an end to your worries about valves coming into contact with pistons because they’re too close for comfort in engagement by the I-VTEC technology, which prevents this from happening at all.

The only downside is that if it breaks or becomes worn down, then anything could happen, so make sure to keep this in check.

On top of that, the valvetrain was also on the list of things to fix during the K-series design stage. A set of roller units has replaced b series’ pad-style rockers. The roller wheels ride directly on the camshaft lobe, decreasing friction and allowing the engine to rev higher.

Honda also altered the way the valvetrain attaches to the head. The lower bearing perch of the B-series is machined into the head, with the upper cap fastened on top. The setup works fine, but if a cam spins a bearing or has a problem, the entire cylinder-head is destroyed. The K’s valvetrain is bolted to the head and is completely removable and replaceable.

Ignition System

Another aspect of the K engines that has been significantly improved is the ignition mechanism. The archaic distributor, spark plug wires, and single coil are no longer used. A new coil-on-plug ignition system is in its place that produces stronger, precisely metered sparks with pinpoint timing precision.

The benefit of computer-controlled ignition is that spark progress may be metered out at precisely the right time. As a result, K series engines are shipped with significantly greater compression ratios peaking as high as 11.7:1 in JDM K20a engines than earlier distributor-based B-series engines.

Engine Potential

Swapping a K-series engine into an older chassis is easier now than a few years ago, but it still has its challenges. The engine’s rotational position contributes to some of the difficulties.

To illustrate, the K series, unlike the B series, revolves clockwise. The exhaust ports are now facing the firewall, while the intake ports are facing the car’s front. The new orientation makes exhaust routing considerably more straightforward, but the engine will require aftermarket mounts to fit into an earlier chassis.

Aftermarket axles will also be required to convert the K-series transaxle to the appropriate Honda knuckles. We won’t go into great length on engine swaps because there are so many variables for each chassis. However, we shall argue that the K-series is a more complicated swap than the B, which can typically be done using factory components such as axles and mounts.

Summary

The B and K series are engineering marvels capable of producing mythical levels of horsepower per liter. A built version of these engines promises to be indiscriminately fun and fast. Yes, the K Series indeed has advantages in virtually every mechanical aspect, but for those who want affordability with style, there is always home on your shelf.

With that, as a consumer, it is essential to understand the different available platforms. A little knowledge goes a long way and will help you make an informed decision when choosing which one is right for your needs. So, in terms of these two engines, it is your call to choose based on the pieces of information we laid out here.

Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this website.