I think we can all agree the internal combustion engine is one of the most important inventions ever, but today we’re going to take a look at the LiquidPiston engine because it just might be the future of all engines.

What is a Liquid Piston Engine?

Now the first question, pretty obviously, is what the heck is a liquid piston engine, and how does it work? I mean, just the name of it doesn’t make any sense.

How can a piston be liquid and still function? And the answer to that is that it can’t, but that’s fine because the liquid piston engine doesn’t use a piston in the traditional sense.

In fact, this entire engine doesn’t really work like a traditional internal combustion engine. In a conventional engine, the piston moves up and down inside the cylinder, compressing the air-fuel mixture, igniting by a spark plug, and that explosion forces the piston downwards, and the crankshaft turns that into rotational power.

In a liquid piston engine, a liquid, which is usually water but it technically doesn’t have to be, is used instead of a solid piston. This entire idea operates based on one principle, which is the principle of liquids being incompressible.

The engine consists of a cylinder and a chamber filled with liquid. When the liquid is forced into the cylinder, it displaces air or another fluid, causing pressure to build up. This pressure can then be used to drive a crankshaft and produce mechanical work.

LiquidPiston the Company

So that’s the idea of a liquid piston engine, but what we’re looking at today isn’t that. What we’re actually looking at is a handful of engines from the company LiquidPiston.

But it gets even crazier than that because the LiquidPiston engine we’re looking at today doesn’t even have a piston at all; rather, it’s a rotary engine.

And funny enough, what we’re looking at in this video is really just a massive evolution of the rotary engine found in Mazda’s old cars.

Honestly, calling it a LiquidPiston rotary engine is just confusing for no reason at all. Regardless of the confusing naming convention, the engines being developed by LiquidPiston, the company, are incredibly interesting and pretty genius in how they work.

And the simplest way to explain how this engine works is to imagine a rotary engine, something like a 13B, for example. Now take the apex seals off the rotor and make them stationary on the housing, then take the intake and exhaust ports and put them on the rotor itself.

And take the shape of the rotor and housing from a 13B and invert it so the rotor is shaped like the housing, and the housing is shaped like the rotor.

LiquidPiston Rotary Engines

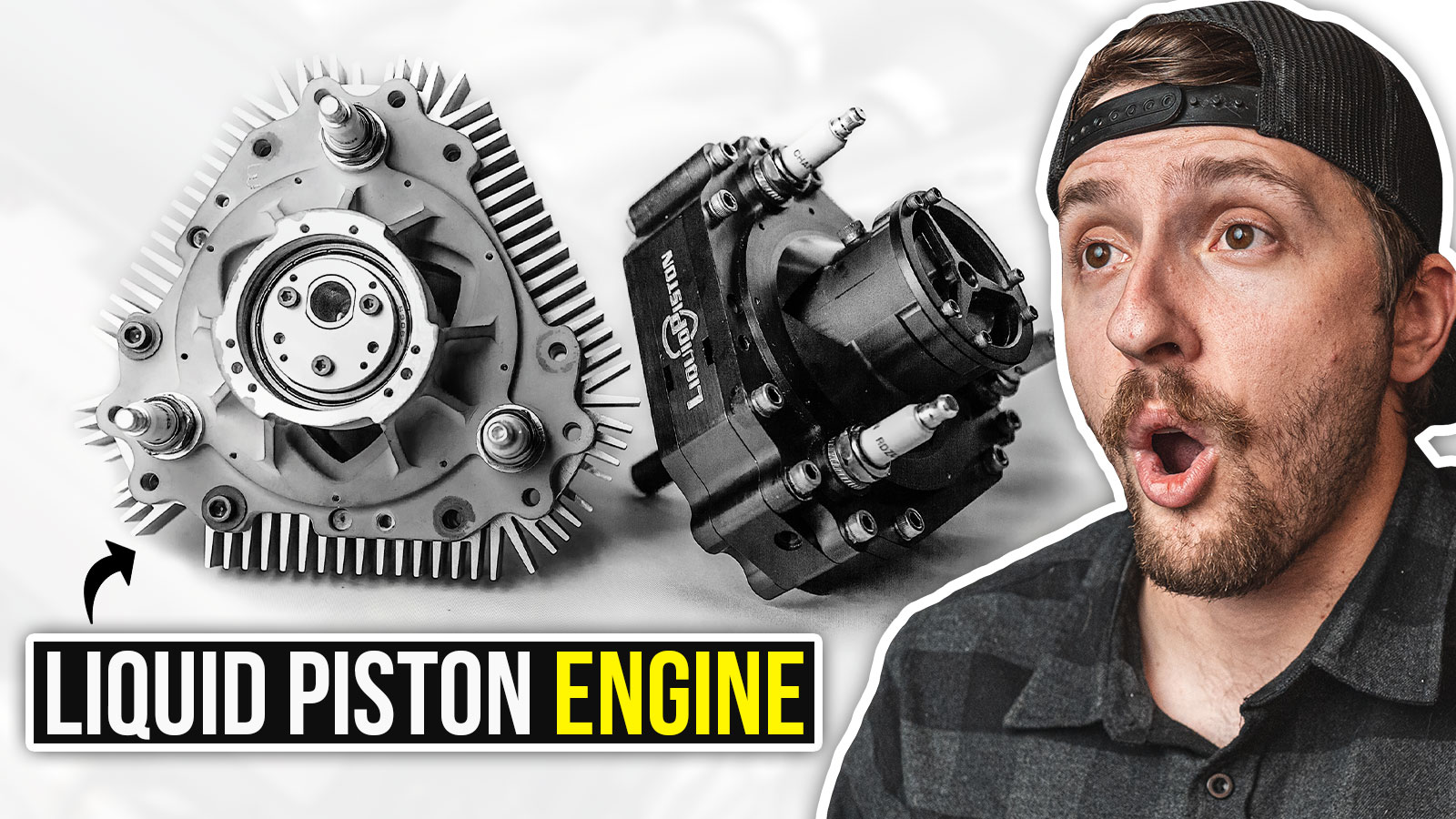

Here we are looking at one of LiquidPiston’s smaller examples of their engines using this principle. There are three working chambers, each with its own spark plug. As the rotor rotates on the eccentric shaft, air/fuel comes through the shaft, and there’s an intake port on the rotor.

As the rotor spins, it creates a vacuum in the working chamber which pulls in the air/fuel mixture from the port on the rotor. Once the rotor rotates far enough, the intake port is then covered as it rotates into the next working chamber.

The first working chamber then goes under compression as the rotor continues to rotate. For a gas version of this engine, this is when the spark plug is used to ignite the air/fuel mixture. For a diesel version of this engine, this is when diesel fuel is injected into the working chamber.

After the combustion occurs, the rotor continues to rotate thanks to the now ignited and expanded air/fuel until the exhaust port then rotates into the working chamber. It then pushes all the ignited mixture out of the working chamber and into the rotor.

Once it is in the rotor, it escapes through one of three exhaust ports on the housing. So just to recap on that, there is one intake that goes through the eccentric shaft, and three exhaust ports on the housing.

With this type of design, for every revolution of the rotor, you end up with three combustion events happening in each working chamber.

And the whole reason behind this is that this design effectively capitalizes on the best parts of an Otto cycle engine, an Atkinson’s cycle engine, and a diesel engine and puts them all into one design, resulting in an unmatched compression-to-expansion ratio.

What does that mean in simple terms? This design is surprisingly effective at harnessing combustion and turning it into mechanical work, all while doing it with the benefit of being physically tiny compared to a standard internal combustion engine.

I mean, seriously, look at this thing. It fits in your hand and weighs roughly 4.5 lbs, but it produces four horsepower!

Now obviously, you have to consider context because 4hp might sound really underwhelming if you’re used to talking about full-sized engines found in cars, but 4hp out of something this small and efficient is absolutely game-changing.

It’s NOT a Wankel Engine

I think it’s important to note, at this point in the article, that LiquidPiston’s rotary engines are NOT Wankel engines. Yes, they are similar, but they work very differently, and as compared to a standard Wankel engine, these engines are improved in just about every single possible way.

In fact, one of the easiest ways to describe this engine is as an inverted Wankel engine. While a Wankel engine has a 3-sided triangular rotor held within a 2-lobed oval housing, this engine has a 2-lobed oval rotor in a 3-sided housing.

LiquidPiston’s X Engine, as compared to a Wankel engine, improves on efficiency, weight, size, vibration, noise, power, and reliability. And because there are really only two moving parts in this engine, a rotor, and a shaft, it’s minimal vibration.

And best of all, the apex seals are located on the housing rather than the rotor, which means the seals experience zero centrifugal force and the seals lubricated through the housing, which effectively reduces oil consumption to that of a standard four-stroke piston engine.

The Benefits of this Design

The benefits of this design are pretty clear. For one, it makes a ton of power of per lb of weight, with LiquidPiston claiming up to 2hp per lb of weight.

For reference, the Ford Coyote is right around 445 lbs, which would make it an 890hp engine if it had the power per lb capability of the engine we’re talking about.

And because the compression-to-expansion ratio is so massive and improved, there is just about no muffler required because exhaust noise is more or less just wasted power.

In terms of efficiency, LiquidPiston again claims a 20% decrease in fuel consumption is possible for spark-ignited gas engines and up to a 50% decrease for compression-ignited diesel engines.

As of right now, LiquidPiston really has three engines that are available: The X-Mini, the X4 diesel engine, and the XTS-210 engine, which is by far the coolest because it’s a two-stroke, supercharged version of this already crazy engine.

Potential Applications

So what’s the application base for this idea? Well, I think it’s safe to say we likely won’t see this engine take over the automotive market. In fact, it might not ever be used in a production car at all. But that doesn’t mean it’s useless.

Think about something like a military UAV, for example. Something like that could massively benefit from a tiny engine outputting absurd amounts of horsepower per pound while also being extremely fuel efficient.

Or even something like a portable generator, where the massive weight and size savings can result in dramatically smaller generators that are much easier to transport. And again, this plays very well into the military applications.

So much so, that LiquidPiston actually secured an $8.3 million dollar contract with the US Army to take this idea and perfect it for portable generators.

And if you don’t believe me about the size of this engine, just look at this photo here. On the left is an XTS-210 engine core, and on the right is a 25hp Kohler KDW1003 engine. Both of these engines produce 25hp, but rather obviously, one is much smaller and lighter.

On the biggest engine of the spectrum, we have the X4 engine, which is a diesel engine with a total displacement of 750cc and outputting 40hp, and again, the size difference here is pretty ridiculous.

Here you can see a standard 35hp diesel engine on the left and the 40hp X4 engine on the right. Both of these are diesel outputting roughly the same power, but one of them is a literal fraction of the size of the other.

Summary

So does this engine have the capability to become the future of all engines? The answer is yes and no. Obviously, product adoption isn’t just simply which product is better than the other, and the road to mass adoption of something like this could take decades, but it is possible.

Rather though, I think this engine has a massive future in commercial uses, particularly portable generators, but it could also be perfect for small unmanned aircraft like military UAVs or even just RC planes.

It could also be a great option for motorcycles, where engine size and weight are extremely important.

Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this website.