In a recent article, we looked at some of the worst engines in automotive history and you guys loved that article, but there were only so many engines we could fit in that one article.

So today, we’re looking at five more of the worst engines in history.

#1 Chrysler 2.7L V6 Sludge Machine

Jumping straight into this, we’re going to look at the world’s sludgiest engine, the Chrysler 2.7L V6.

This engine came to be from the belief that Chrysler needed a more advanced, lightweight, and efficient engine if they wanted to come out of the 1990s in a strong and powerful way.

With this in mind, a newly designed V6 engine was created with an all-aluminum construction, dual overhead cams, four valves per cylinder, and much more.

Really, the 2.7L engine we’re talking about was developed from the 3.2L engine, which was developed from the 3.5L engine.

The 2.7L is part of its own engine family, but it was most definitely derived from the earlier engines we just mentioned.

The biggest problem with 2.7 V6 engines is actually the water pump gasket leaking coolant into the oil system and ultimately diluting the oil.

That alone can cause a lack of lubrication and sludge, but it gets even worse thanks to the ineffective crankcase ventilation system.

Quite a few of these engines ended up failing because of the oil turning to sludge and eventually leading to loss of oil pressure and, ultimately, the engine failing in one way or another.

But, Chrysler made things even worse by hiring a third-party company to handle the warranty claims regarding sludge issues for this specific engine.

And that third party company rarely ever approved any claims, which meant a huge amount of Chrysler customers got completely screwed over.

Can you imagine how frustrating it must’ve been to have a relatively new car and the engine to turn its own oil into sludge, and then the warranty is denied and you’re left with a broken car because of bad engineering?

Outside of that pretty catastrophic issue, though, the 2.7L isn’t a terrible engine, but it’s far from a great engine.

And as long as you don’t miss an oil change, it might survive. Maybe.

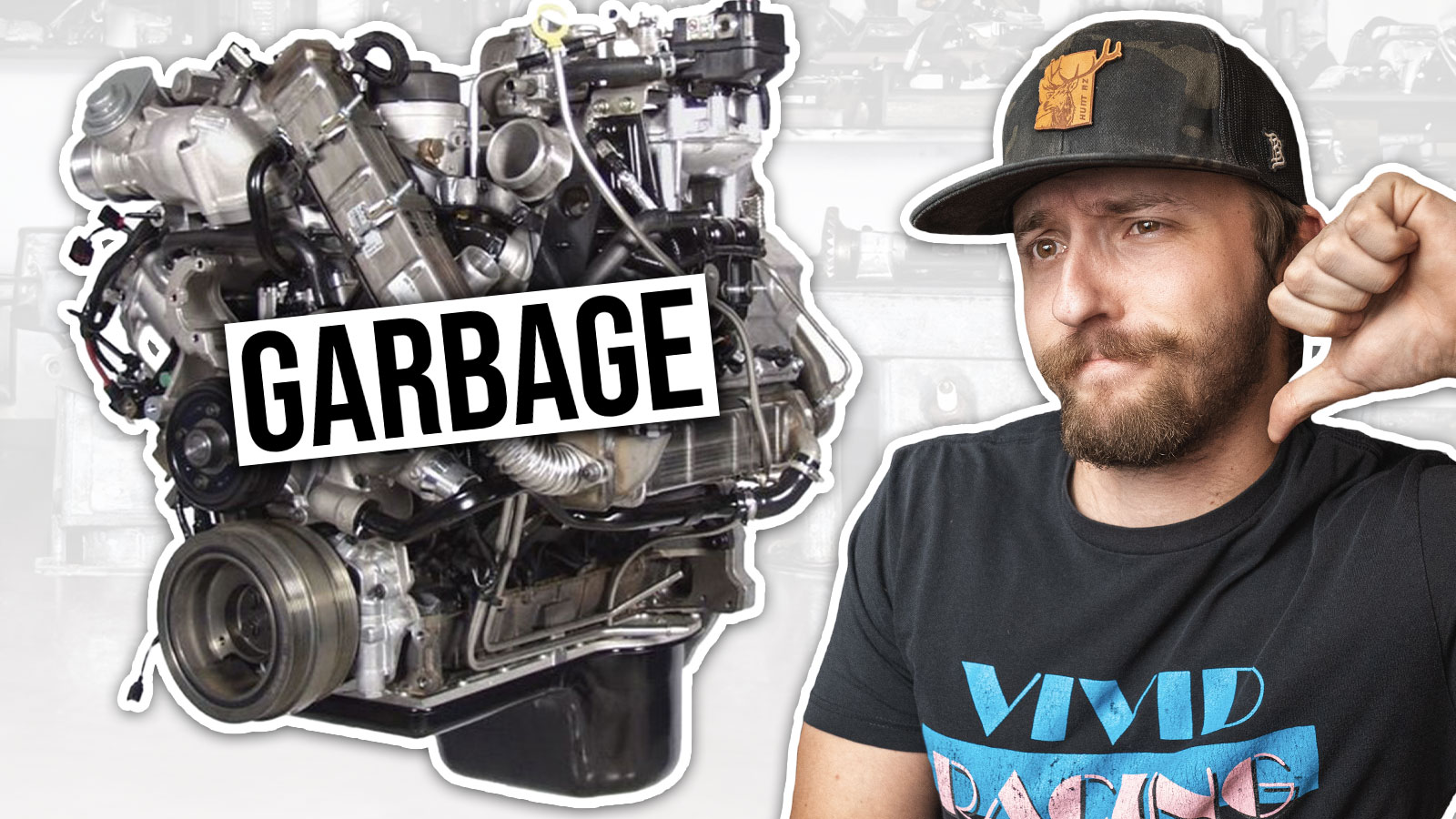

#2 6.4L Powerstroke

In our last article, we mentioned the 6.0L Powerstroke as a terrible engine but plenty of you left comments asking why I didn’t include the 6.4L Powerstroke, so here we are talking about it in this article.

And for those who aren’t aware already, the 6.4L Powerstroke is regarded as one of the worst diesel engines of all time. It’s quite literally referred to as a throwaway engine by loads of diesel shops, because it truly is a throwaway engine.

The problems start with the fact that Navistar International put together this engine in a hurry on behalf of Ford in order to meet the upcoming emissions restriction changes as well as the brand’s image after the train wreck that was the 6.0L Powerstroke.

But they ended up somehow putting together something that was even worse than the 6.0L.

The problems start with the diesel particulate filter and how the regeneration system works on these engines, which ultimately put cylinders #7 and #8 under more heat than the other cylinders which then has a tendency to melt or even crack the pistons.

Then the exhaust gas recirculation system has its own set of problems with getting clogged and breaking, plus the EGR valve has more or less the same problem.

Then there are problems with leftover sand inside the coolant passages from when the block was cast, which can clog the oil cooler and shoot your oil temps through the roof.

On top of all that, there are still problems with the head bolts if you turn the power up too much. Plus the high-pressure fuel pump and injectors have their own separate issues.

The list really just keeps going and going.

The 6.4L Powerstroke was the final straw in Ford’s relationship with Navistar and they developed their own engine without Navistar’s help, which then became the 6.7L Powerstroke. An engine Ford is still using to this day.

The 6.4L Powerstroke is good at one thing, making lots of power when tuned. Otherwise, it’s a complete trash.

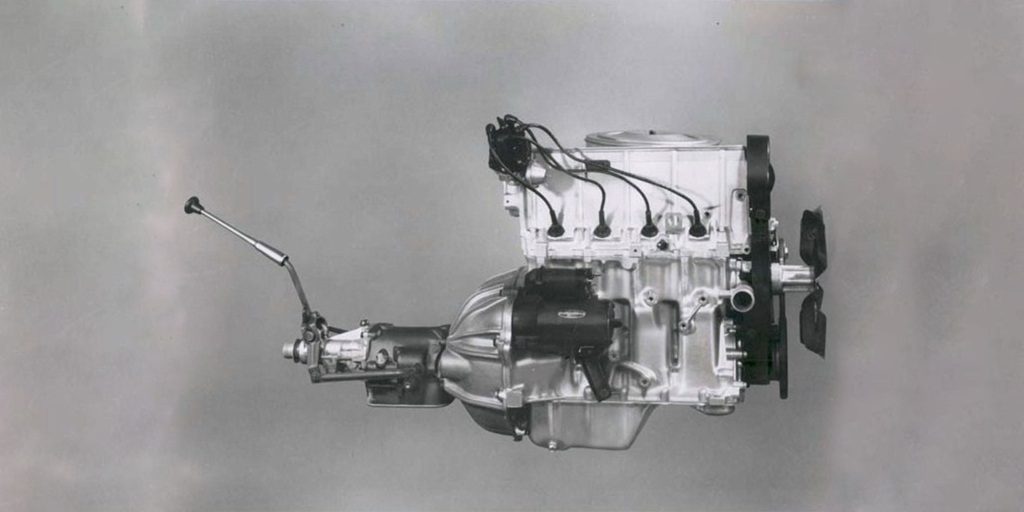

#3 2.3L Vega

Moving away from diesel engines, let’s take a look at a small and funky American-made four-cylinder engine. And no, not the Iron Duke because we’ve already flamed that engine enough. Instead, we’ll be looking at the 2.3L Vega engine.

Now this engine is particularly interesting because it’s backward compared to any modern engine or basically any engine ever.

And I don’t mean physically backward, but rather that the block and head are made from the wrong materials.

What do I mean by this?

Well, for a lot of engines the cylinder block is cast iron or cast aluminum, and the cylinder head is cast aluminum. Now obviously, all iron engines are a thing, but that’s beside the point.

The Vega, on the other hand, used an aluminum block with an iron head.

And this engine was designed to be lightweight, efficient, and cheap to produce. All of these are important elements when designing a car for the compact market.

But none of that matters because these engines basically ended up recycling themselves while you were driving.

With the aluminum block, GM forgot one very important thing, to use steel cylinder liners.

Without steel liners, the bare block has to act as the cylinder walls and the particular aluminum the Vega engine is constructed from isn’t capable of withstanding that.

And I think it’s very important to note that aluminum engines without steel cylinder liners are not problematic on their own.

Audi, BMW, Mercedes, and Porsche have all used linerless aluminum engines in the years since the Vega engine.

That problem was made worse by the Vega’s tendency to kill head gaskets anytime it overheated because its aluminum block expanded faster than the iron head.

But overheating this engine came with an even worse problem: it broke down the silicon content of A390 aluminum, which left soft spots on the cylinder walls that would eventually become scuffed and scored by the pistons.

And unlike an engine with cast iron sleeves that be repaired and reused, the Vegas block was irreparable, meaning the engine block had to be thrown out in the case of cylinder wall damage.

And all of that was made even worse because coolant overflow tanks were quite literally not even equipped in early Vega models, which meant that coolant expansion resulted in coolant loss, compounding the aforementioned problems into one big nightmare of an engine.

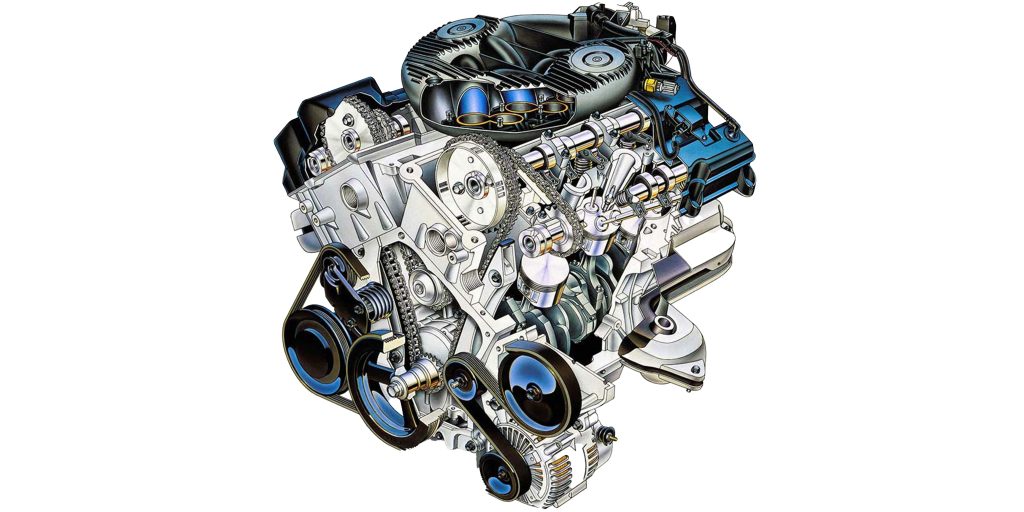

#4 Theta II

This next engine is something I didn’t expect to ever really put on a list of bad engines because the company behind it has produced some incredibly reliable vehicles over the last few decades.

But after the mass recalls for them exploding prematurely, I think it’s safe to say the Hyundai Theta II engine isn’t exactly a great engine.

The whole problem revolves around metal debris in the engine that’s left over from the machining process when manufacturing the crankshaft.

If the debris isn’t removed correctly from the crankshaft’s oil passages, it can then restrict oil flow to the connecting rod bearings and generally kill your engine.

That’s straight from the recall report and I’ll leave that linked down in the description if you want to check it out yourself.

And because Hyundai used the Theta II for quite a few cars, the number of potentially affected cars and people is around half a million. At least according to the report put out to the public.

Interestingly, you can keep this issue to a minimum with more frequent oil changes than Kia or Hyundai initially recommended for the affected vehicles. But that doesn’t guarantee the engine will live.

There are theories, however, that suggest that this issue is actually worse than Hyundai claims, as they say that engines produced in their Alabama plant were the source of this problem, but there had been reports of the engines made in Korea also exploding in similar fashion.

Regardless, it’s a pretty severe problem, but on the bright side, Hyundai seems to be handling it pretty well.

From reports online, the general consensus is that Kia or Hyundai will replace your engine under warranty fast and without a fuss, which is a breath of fresh air to see an automaker actually take care of their customers instead of just trying to screw them over to save a buck.

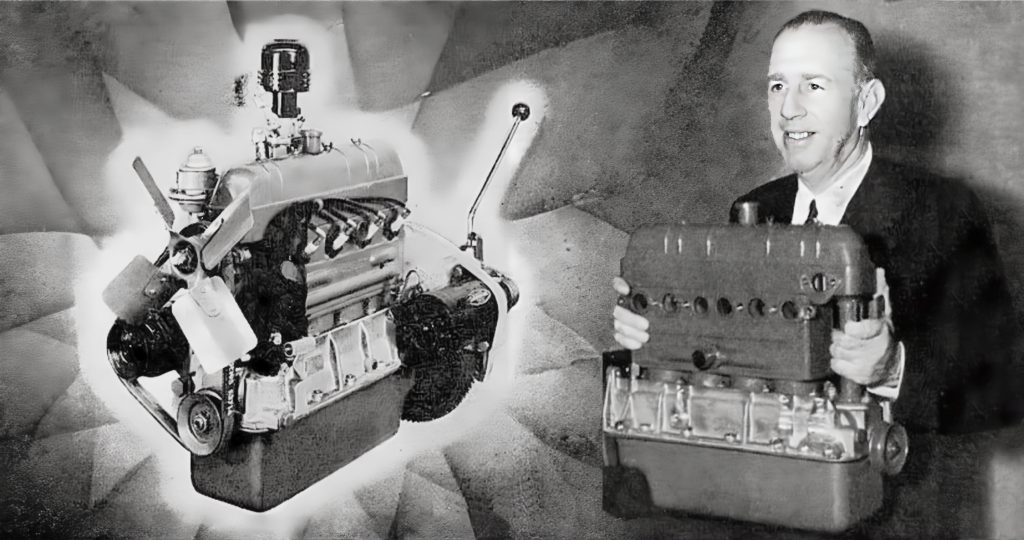

#5 Crosley COBRA Engine

Now this last engine I don’t really fault for being a bad engine because it was a piece of automotive innovation that just simply didn’t work, and that’s the Crosley Cobra engine, aka the sheet metal engine.

You’ve probably never heard of this engine, and well, that’s for a number of reasons. One, it’s old, and two, it had a pretty short lifespan from just 1946 to 1949, but the concept for this engine design was in the works in the 1930s and was patented in 1937.

The COBRA name is actually an acronym for COpper BRAzed, which is a manufacturing method in which the cylinder block and head are brazed together, but this requires building them from pressed steel parts rather than cast parts.

Throughout World War II, Crosley developed a number of prototype engines for the U.S. military using this process and design.

With the development they did on behalf of the army, they ended up with a small four-cylinder engine that they later adapted to plop into their Crosley civilian passenger car for 1946.

How this works is that the cylinder block and the head are one piece, and the whole unit is bolted to a cast aluminum crankcase that handles the crankshaft.

And an interesting benefit to this type of design is that there is no head gasket to fail. So, at least you don’t have to worry about that.

But you do have to worry about something far worse, corrosion.

Back then, coolant wasn’t what it is today, and specifically, it wasn’t nearly as anti-corrosion as it is now, and with that, the cooling jackets inside the Cobra engine develop corrosion is eventually end up leaking.

Even with absolutely perfect maintenance, you’re unlikely to see over 60,000 miles of use out of this engine.

For something that wasn’t maintained perfectly, the life expectancy can be quite a bit worse.

But although they break a lot, the Cobra engine is very interesting and definitely an important piece of automotive history.

Plus, it had some real benefits, but that doesn’t really matter now because we’ve been using cast heads and blocks ever since the Cobra engine came and went.

Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this website.