Toyota did not make a V12 engine until the release of this engine, and it is the only V12 that Toyota made throughout their automaking career. However, these are not your ordinary engines as they are used for specific purposes – and sold mainly for the Japanese Market.

Join me as we discuss the details regarding the 1GZ-FE’s engine design, applications, technologies, reliability, and many more.

What are 1GZ-FE Engines?

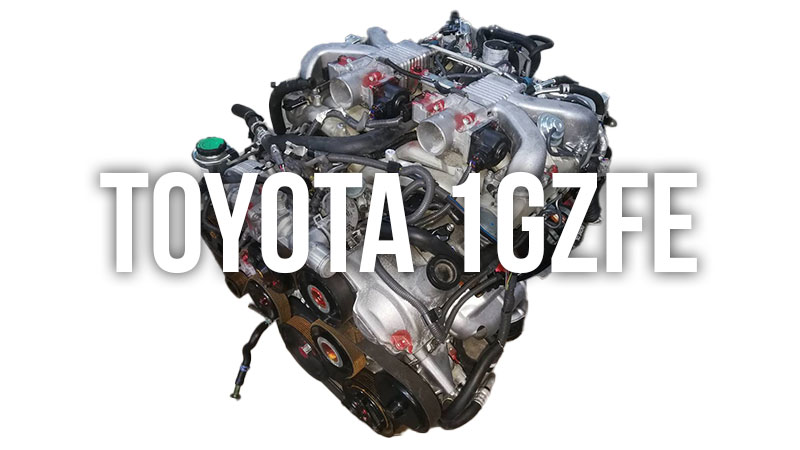

The Toyota 1GZ-FE engine is a quad-cam, naturally-aspirated, water-cooled, V-type, twelve-cylinder gasoline engine produced by the Toyota Motor Corporation from 1997 until 2016.

This engine is Toyota’s only V12 to come out and is mainly sold in the Japanese market. 1GZ-FE is the status of a luxurious and grand lifestyle; as it is equipped on Toyota Century, governmental and business officials use modified versions to suit the Japanese Imperial Household.

The engine features an alloy block and heads, forged steel crankshafts, and six main bolts.

Toyota introduced the use of an Iridium pole spark plug, slant-squish combustion chamber, intelligent electronic throttle control system (fly by wire), and continuously variable valve timing system (VVT-i).

The intake manifold is implemented with ACIS or Acoustic Control Induction System and sequential fuel injection for fuel supply.

These features helped the 1GZ-FE engine achieved its supreme quietness and overwhelming smoothness while producing the highest torque among the same displacement engines at low to medium engine speed.

Furthermore, 1GZ-FE attained high reliability and good fuel economy that exceeded any other competitors in that category.

Engine Specifications and Design:

- Production Run: 1997 – 2016

- Cylinder Block Material: Alloy

- Cylinder Head Material: Alloy

- Configuration: V12

- Bore: 81 mm

- Stroke: 80.8 mm

- Valvetrain: Chain-driven DOHC with four valves per cylinder

- Displacement: 5.0 L (4996 cc)

- Compression Ratio: 10.5

- Weight: 650 lbs.

- Max HP: 308 HP at 5,200 RPM

- Max Torque: 355 lb-ft at 1,200 RPM

The Toyota 1GZ-FE is one of Toyota’s BEAMS family (Breakthrough Engine with Advanced Mechanism System), such as the 3S-GE on the Altezza. The 1GZ-FE is basically two straight six-cylinder engines sharing a single crank.

There are dedicated left and right cylinder bank inlet manifolds, EFI systems, and throttle bodies. There are also separate ECUs for each bank, for whenever a failure occurs in the engine, it can run as a six-cylinder engine.

The 1GZ-FE is front-loaded and longitudinal. The engine’s cylinder bore and piston stroke are similar to those of 1JZ-GE machines – 81 mm cylinder bore and 80.8 mm piston stroke; but we are not sure about other components if they are compatible to swap like the pistons and connecting rods.

The rated output of the 1GZ-FE per the Japanese Manufacturer’s Agreement is 295 HP at 5,200 RPM, but the actual power of the engine is estimated to be in the 308 HP range. The maximum torque output is 355 lb-ft at 4,000 RPM and is available from as small as 1,200 RPM.

The cylinder block is made from alloy with a 60-degree bank angle that utilizes thin-wall cast iron liners cast inside. The 1GZ-FE, which is a V12, is slightly narrower than the 90-degree 1UZ-FE, a V8.

Pistons are made from aluminum and utilize a taper squish design with semi-floating piston pins. The connecting rods are sintered and forged that are asymmetric, made explicitly for left or right bank usage only.

The forged crankshaft has twelve balance weights and seven aluminum bearings.

The 1GZ-FE is also known for its smoothness. This is mainly due to the shorter interval between the succession of power strokes that occurs thrice fast in a four-cylinder.

It has slant-squish combustion chambers, variable valve timing – intelligent (VVT-i), and iridium spark plugs combined to enable smooth engine operation and stabilize the combustion. However, the VVT-i is only integrated into the intake cams.

Intake valves are 30-mm in diameter, and exhaust valves are 24.5 mm- and both have 5.5 mm diameter stems. The valve angle in the heads is 24.3 degrees. The valve adjusting shim sits right at the top of the aluminum alloy valve lifter buckets and has a titanium coating.

It is integrated with a continuously variable valve timing that adjusts the valves to suit different driving conditions to increase torque, power output, and fuel efficiency to reduce emissions.

Along with the continuous effort to increase the torque in the low to mid-range is a variable-length intake system that interchanges between two set intake lengths. That is coupled with an advanced engine block rigidity and reciprocating mass that results in 10% less vibration.

The titanium-coated valve shims and low viscosity 5W-30 engine oil are used to minimize friction loss.

The 1GZ-FE is run through a Direct Ignition System (DIS) waste spark set up. That is having the front six cylinders have a mounted coil directly on top of the spark plug.

Each coil has a plug lead pigtail attached to another plug which is firing in pairs. And the fuel system is a regular supply and return setup; fuel is supplied via a sequential injection system.

The firing order is 1-4-9-8-5-2-11-10-3-6-7-12 with the following spark plug pairs: 1 and 11, 3 and 9, 5 and 7, 2 and 12, 4 and 10, and 6 and 8.

There are two crank angle sensors installed 180-degrees apart to read from a standard timing rotor. At the same time, the position of the camshaft sensor is placed to the rear of each intake camshaft with three evenly spaced teeth positioned on the timing rotors.

The 1GZ-FE is integrated with the Electronic Throttle Control System – intelligent (ETCS-i), which indicates the position of the accelerator pedal that transmits the signal to the engine ECU.

This, in turn, drives the throttle motors that open the throttle butterfly, driving in a standard throttle position throughout.

Throttle motors are used for cruise control, idle speed control, traction control, and ABS.

The camshafts are driven with three timing chains, not a toothed belt. The tensioner is oil pressure controlled and spring-loaded. There is only one sump location for the 1GZ-FE, with the bowl at the front.

The sump design is an ordinary one in that there is a pressed steel sump bowl and alloy upper pan. The bowl is wide and holds approximately 8 liters of oil.

Some applications of the 1GZ-FE engine:

- 1997 – 2016 Toyota Century

- 2006 – 2008 Toyota Century Royal

A version of the 1GZ-FE runs on compressed natural gas, and it is called 1GZ-FNE. This engine produced 255 HP and 299 lb-ft of maximum torque. It appears only on one vehicle, the 2003 – 2004 Toyota Century.

Engine Tuning, Upgrades, and Modifications

Engine swaps are more common than tuning the 1GZ-FE. This V12 is sometimes placed on Supras and other vehicles that want to explore the true abilities of this engine.

But some owners placed parallel twin turbochargers in the engine and produced at least 1000 HP. They replaced the internals like the pistons and connecting rods from the 1JZ and 2JZ-GTE engines.

However, it is challenging to find ECU aftermarkets since you have to match the engine’s ECU. It employs multiplex comms between the Body ECU, engine ECU, and ABS/traction control ECU.

Problems Surrounding the 1GZ-FE Engine:

1GZ-FE is no exception when it comes to engine issues and concerns. It is always inevitable and unwarranted to secure that there are no troubles that might arise. Here are some issues that might affect the engine throughout its service.

Though not considered a problem, it is more of a dilemma because the 1GZ-FE engine might not run if the ECUs are removed or replaced with another that is unsuitable for the machine itself since the factory-released ECU is not suitable linked together with the whole system.

So with that, if you are planning to buy an ECU, make sure that you remade everything to use a single ECU only.

Then there are also concerns regarding the two throttle bodies, both driven by wire and independently controlled by the ECUs. With a stand-alone, you may be forced to use a cable throttle; then, while cruising or maintaining idle, you may experience fine-tuning issues with the cable system versus the drive-by-wire.

Summary

Toyota 1GZ-FE can be underwhelming since its production numbers are almost the same as most straight-fours or six engines we encounter every day.

Its only appeal to the community and the industry is mainly due to its ability to support the vehicle if anything goes wrong inside the hood – or we say backup plan. It is also a low-maintenance engine since the recommended oil for the engine is a 5W-30 which is of high viscosity that can last up to 6,000 miles

To add to that, the camshafts are driven with chains, so you do not have to change them now and then, which makes it a plus. The technologies incorporated in the engine are also ahead of their time and well-researched.

From the Z mechanism down to the smallest detail. Though it has some problems and issues that may arise since 1GZ-FE is a long-standing engine and is not getting any younger, changing any necessary parts would help big time sustain the engine’s useful life.

I hope that this simple discussion helped you understand the 1GZ-FE’s design, applications, issues, potential, reliability, features, and overall impact on the automotive society and community.

Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this website.

Hi,

Would you know the dimensions of the 1GZFE? I have been told it is similar in size to a 1uzfe (around 800mm(h) x 800mm(l) x 800mm(w)) . I am considering swapping one into a car that had a 6 cylinder engine originally. Any advice greatly appreciated.

I don’t have exact dimensions but this engine have been dropped in a IS body (1st gen). you can find it by searching IS500 on youtube, or v12 IS.

Since the engine is a 2.0 straight 6, you can learn for that that the engine is probably slightly bigger, but not this long, and not this big.

Thank you for your response and advice, greatly appreciated!

I’m looking buying a Toyota century v12. It has 105k miles on it. Is that high mileage for the v12?

Hello !

Do you have a disassembled engine?

Could you tell me internal dimensions, for example, crank pin dimensions and length.

thanks for the reply

Engine lack of power