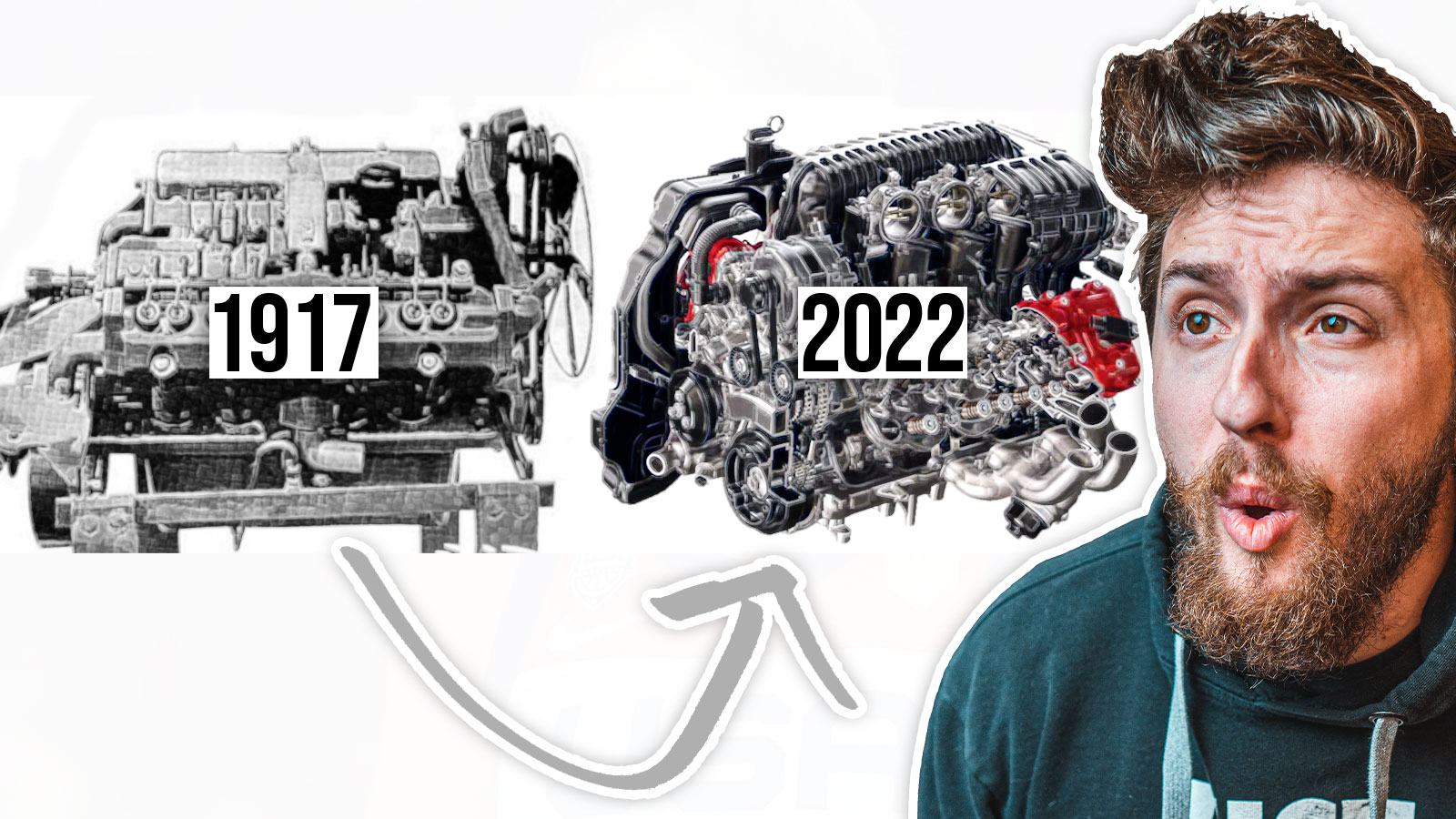

V8 engines are nearly synonymous with American-made cars, and Chevrolet is one of the remaining American automobile powerhouses remaining. Chevy has been using V8 engines in their cars are trucks since as early as 1917, although we didn’t see the now famed small block engine until the 1950s.

From then till now, Chevrolet has produced hundreds of different V8 engines, some for trucks, some for cars, some for supercars, and a little bit of everything in between. With that in mind, it’s time we take a deep dive into the world of V8 Chevy engines and look at their best engines ever.

Preface

Please keep in mind that this list we’re about to go through is sorted in no particular order, and there are really probably like 30 engines that could be on this list, so quite a few engines are left out for the simple fact that the list needed to be condensed down.

And before we get into the article, drop a comment down below, letting me know which one you think is better: GM LS or Ford Coyote. That article is coming soon, so I’m curious to see what you guys comment in the meantime!

Series D V8

What a more fitting place to start the list out than all the way back in 1917. We had Woodrow Wilson in charge of running the entire US, we got involved in World War 1, and Chevrolet introduced their new Series D cars. The series came in two body styles, a 4-door 5-passenger sedan, and a 2-door 4-passenger Roadster.

But we’re not here to talk about the car itself, but rather the engine under the hood known as the Series D V8, which was a new engine designed by Chevy that was supposed to deliver new levels of power, performance, and reliability. This was a small, by today’s standards, 4.7L engine, and it was Chevy’s first-ever V8 engine.

Hell, it was one of the first overhead-valve V8 engines ever. The design of this engine has a lot of weird stuff that we haven’t seen in the modern age, including a partially exposed valvetrain, nickel-plated rocker covers, a gear-driven generator for the distributor, the starter in the valley of the block, and much more.

Plain and simple, it was and is kind of a goofy engine, but that’s to be expected as their first-ever V8 engine. All in, this engine output an unbelievable, earth-shattering 36hp at 2700rpm. Thank god for innovation because a 36hp Camaro would be pretty terrible.

Unfortunately, this engine had a very short life from 1917 to 1918 when the Series D ceased production, which meant a stop on the engine production too. It wasn’t until 37 years later that we saw their next V8 engine.

1st Gen Small Block V8

Speaking of which, the 265ci 1st generation Chevy small block is the next engine on our list. Well, actually, let’s just look at the 1st gen small block as a whole. Now obviously the includes a range of engines: whether it’s the 265ci or 283ci engines that powered Chevy through the 1950s and 1960s or the 305ci and 350ci motors that dominated street performance in the 1980s.

Regardless if you’re a fan of small-block engines or not, it’s really hard to overstate their importance to not just Chevy, but for American cars as a whole. Plain and simple, the Chevy small-block is one of the most important engines in all of automotive history.

It set the tone for what Chevy was about and lay the groundwork for them to continue producing V8 engines all the way up until today. And while today’s V8s are rather obviously a pretty big departure from the 1st generation small block, it’s because of the small block that we have today’s LS and LT engines.

The small block was a revolution in terms of power, simplicity, ease of maintenance, reliability, parts interchangeability, and so much more. Dozens of first-generation small block variants range from mild to wild, with horsepower approaching the 400 mark in the early 1970s.

As electronic fuel injection entered the picture in the 1980s, it became a common feature in performance models like the Camaro and the Corvette, as well as the later TBI applications in trucks and vans. And while I’m not a big of TBI small block engines, again, it laid the groundwork for much better engines to be developed.

454ci LS6

Alright, enough with the small blocks. Yes, they’re important to Chevy’s history and the entire US automotive industry, but they’re not particularly interesting unless you dive into very specific variants. So, let’s look at something a little bit more interesting, a little bit more powerful, and a little bit spicier, starting with the LS6.

And no, we’re not talking about the LS6, and no, not the hopped-up LS1 found in the C5 Z06 and CTS-V, but rather the older 454ci LS6 that is the arguably the absolute peak of all big-block engines from GM.

When the LS6 454 was first offered by Chevrolet in their 1970 catalog, it was intended to rule the streets by building on the same Mark IV design architecture that we saw with the 427ci V8 that came before it.

And by doing so, the LS6 454 maintained the 427’s 4.25-inch bore, but it increased the stroke to 4 inches, and it was offered to the general public in two distinct versions:

There was the more entry-level 360hp LS5 that you could find in full-sized cars like the Caprice and Chevelle when equipped with the right packages, but we’re not here to look at the entry-level engine.

The bigger, nastier LS6 could be optioned in the Chevelle and El Camino SS 454 cars with RPO code Z15/LS6, although it certainly wasn’t a cheap option which is partially what makes it so rare.

And you might be wondering, what set the 454 LS6 apart from the more modest LS5? And it’s actually quite a few different things. For one, the compression on the engine was 11.25:1, and its cast iron rectangular port heads featured 2.19-inch intake valves and 1.88-inch exhaust valves.

It also featured a solid lifter camshaft versus the hydraulic lifters on the LS5, with a .520-inch lift and a 316-degree duration. Combine all that with the improved intake manifold, forged pistons, and giant 800cfm carb, and you end up with an absolutely nasty combo making tons of power and even more torque, to the of 450hp and 500lb-ft.

Although it’s rumored that the engine’s output was underrated by GM to keep insurance companies from cranking premiums through the roof.

I think that it is worth noting that the Corvette could also be had with the 454 LS6, but not until 1971, and by then the EPA came knocking, so the Corvette’s engine had the power decreased to 425hp, but it also got the addition of aluminum cylinder heads rather than iron, saving about 50lbs of weight.

And as you probably know, GM eventually re-used the LS6 name on another engine, which was the 5.7L LS motor found in the C5 Z06. As to why they reused the name, I’m not exactly sure, but regardless, the 454 LS6 and 5.7L LS6 share absolutely nothing in common other than the name and the fact that they were both only available for a very limited time in very limited applications.

427ci ZL1

The next very big engine from nearly the exact same timeframe as the 454 LS6 is the 427 ZL1 engine. At this point, Chevy had a history of powerful engines that ruled stoplight to stoplight racing and drag racing. These are engines like the L78, L88, L89, and so on. But, the most brutal of them all, the nastiest, most powerful engine, was the ZL1.

This engine was born when a gentleman named Jim Hall began using all aluminum 427 cubic inch engines in his Chaparral Can-Am race cars which saw great success and then caught the attention of Fred Gibb, who was a Chevy dealer in Kansas City, and Dick Harrell, who had previously worked with Gibb to build a drag and street cars.

At the time, Chevrolet’s central office had a program that allowed a dealer to order a car that was equipped with options that normally weren’t installed. This meant that a dealer could order a certain mix of parts and options, and it became a central office production order, also known as COPO.

In 1968, Fred Gibb ordered 50 1968 L78 Novas under the COPO program with M40 automatic transmissions in place of the usual four-speed gearbox. This was the first time Chevy had ever placed an automatic transmission behind a solid-lifter engine for a production car, and by building 50 of these, the Nova was qualified to race with an automatic as per NHRA rules.

Fred Gibb then chose to apply this same strategy to the 1969 Camaro. He did this even while knowing Chevy was planning to release an all-aluminum version of the 427ci L88 engine. However, it would have open-chamber heads. The engine was designated ZL1 and had been planned for the Corvette.

Compared to the L88, the ZL1 had a number of very important changes and parts that allowed it to make quite a bit more power and do so reliably. In the end, the ZL1 engine was rated at 430hp and 450lb-ft. But, later dyno testing of factory ZL1s revealed its output was quite a bit more, in the 550hp range.

Between GM, Fred Gibb, and Dick Harrel, they developed COPO package 9650, which placed the ZL1 engine in the 1969 Camaro to qualify it for the 1969 NHRA season. With a massive 150-lb weight savings of the ZL1, it was sure to make the Camaro competitive against Mopar’s Hemi for drag racing use.

The 9560 COPO package started with an L78 equipped Camaro, but with the 427 ZL1 under the good, plus 14×7 wheels, F41 heavy-duty suspension, a cold air induction cowled hood, larger radiator, radio delete, front disc brakes, and a 4.10 rear gear with an LSD. Plain and simple, these 9560 COPO Camaros were meant for straight-up racing.

Unfortunately, when Gibb ordered 50 of these Camaros, Chevy hadn’t informed him of a new corporate policy that passed the extra cost onto the dealer and then ultimately the customer, rather than Chevy absorbing the costs in the form of R&D expenses.

What that means is that Fred Gibb was expecting a $400 option cost for the ZL1 packaged Camaros but instead was hit with a $4,160 of options on top of the base Camaro price, which resulted in a sticker price of $7,200, which was pretty insane for a Camaro of the time.

Very few dealers could finance that kind of inventory order or even sell 50 Camaros that cost more than a $4,700 Corvette. And as such, Fred Gibb felt that Chevy had kind of screwed him over with the pricing that he wasn’t expecting, so they negotiated a deal to send back 37 of the 9560 COPO Camaros, which were then distributed through Chevy’s dealer network and sold. Those 50 cars plus the 19 additional cars ordered by various dealers brought the total up to 69 1969 ZL1 Camaros produced.

And to give you an idea of just how fast the ZL1 Camaro was, a stock version was capable of running a 13-second quarter mile at 110 mph. That’s fast for a production street car by today’s standards, let alone 1969 standards.

C4 ZR1 LT5

Jumping forwards a bit, let’s take a look at the LT5, but not the one under the hood of the C7 ZR1, but rather the one under the hood of the C4 ZR1. God, I really hate that Chevy uses the same naming for their engines over and over and over. It makes everything so confusing. Anyways, this engine was a marvel of engineering at the time of its release.

You have to remember that throughout the 50s, 60s, 70s, and all the way up to the 90s, GM was offering their small block and big block engines in various forms, but they were all very similar with the same cam-in-block design. Hell, Chevy is still using that format to this day, but we’ll get to that later.

When they were designing the ZR1 package for the C4 Corvette, they knew they were going to need something better. If this package was meant to be the pinnacle of Corvette performance and, ultimately, Chevy performance, they couldn’t keep using the old dinosaur engines, so they teamed up with Lotus to develop something much better, or at least better on paper.

I think it’s also worth noting, at this point, that in 1986 GM acquired a 91% stake in Lotus after Toyota sold its ownership stake to GM. So, it’s not like GM went to a random company to help them design and build the ZR1, but rather they simply leveraged a company that already existed in their portfolio.

When the Corvette division was developing the ZR1 package, they approached Lotus for help with the engine and the entire platform. With some help and guidance from GM, Lotus went on to design a new engine that was then named the LT5. This new engine was a massive departure from the existing L98 V8 engine found the in standard C4 Corvette.

It uses an aluminum cylinder block with the same bore centers as the L98 but with dual-overhead cams and four valves per cylinder. It also used a Lotus-designed air intake system that provided a surprisingly wide power band. Unlike the L98, though, the bore size was decreased from 4″ down to 3.9″ and the stroke increased from 3.48″ to 3.66″.

This engine also features aluminum cylinder liners, a cast-aluminum oil sump, hydraulic lifters, an 11:1 compression ratio, and a whole bunch more. Plain and simple, it was designed as an extremely high-performance naturally aspirated engine.

One of the parts that I find interesting about this engine, especially compared to just about any other gas engine from the 1990s, is that the LT5 held a ridiculous 12 quarts of oil. To put that in perspective, the standard L98 engine only held 5 quarts.

To keep everything cool, GM employed an improved cooling system with a larger radiator to keep the operating temperatures similar to the L98-powered C4 Corvettes.

All this lead up to a pretty impressive 375hp, which sounds pretty bad compared to the performance-oriented engines we discussed earlier in the article, but you have to remember that 1990s performance cars were severely restricted by the lovely folks at the EPA.

For reference, a standard 1991 C4 Corvette produced 250hp. So, for the ZR1 to jump to 375hp while using the same displacement as the standard Corvette without the introduction of forced induction is quite impressive.

Strangely enough, this engine was complicated enough for GM to realize that none of their standard production facilities could manage the extra workload, so they contracted the engine production out to Mercury Marine to assemble the engines.

Supposedly, the engine assembly was about 95% drilling and boring completed at the Mercury Marine production plant. And interestingly enough, the engine was almost entirely assembled by hand, and then Dyno tested it before being sent to Chevy for them to plop into the ZR1 C4 Corvette.

Later versions of the C4 ZR1 had their power bumped to 405hp by modifications from Lotus in the form of cylinder head changes, exhaust system, and more. But, it was short-lived, as in 1995, the ZR1 was discontinued after selling just shy of 7,000 units during its production run.

5.7L LS1

Alright, the moment you’ve all been waiting for is when we finally jump up to the modern age with arguably GM’s greatest creation ever: the LS. More specifically, we’re putting the LS1 on this list and this article because, as its name implies, it was the 1st engine.

Compared to the small-block engines before it and then the god-awful TBI engines, the LS1 was a far departure from it all, but it also was and is astonishingly similar to the earlier engines and, at the time of its release had a lot of people wondering with Chevrolet had made a bad move by not moving to overhead cams as Ford had done in the 1990s.

Regardless, it’s hard to understate the importance of the original LS1 engine, which birthed the Gen III small-block design that then sprouted the Vortec truck engines and so much more.

The LS1, specifically, was first debuted in the 1997 Chevy C5 Corvette. This is a 5.7L engine, and it features an all-aluminum design. It also features coil near-plug ignition, and various other new engine management features.

And as I mentioned, these new features made it vastly greater than the previous generation’s small block. And by 1998, the LS1 replaced the LT1 found in Camaros and Firebirds.

When they moved from the old small-block design to the new Gen III design, they massively beefed up the foundation of the engine by switching to a Y-block design. This also then allowed them to use six bolt main mains, four bolts vertically and two horizontally, which GM engineers named snap-fit cross-bolting.

On the top end, Chevrolet took it even further by integrating the use of extra long head bolts that thread deep into the block to minimize cylinder bore distortion and variation in the head bolt torque spec, as well as improving the clamping force to the block.

Compared to the old small blocks, the camshaft was raised up and farther away from the crankshaft, which allows them to clear a 4-inch stroke crankshaft, which they didn’t leverage initially but later did to create the 7.0L displacement of the LS7, but more on that in a moment.

To further increase the strength of the top of the engine block, they used a valley plate, which is simply a large metal plate that covers the valley where the lifters reside. This increases the strength of the block by bolting each side of itself onto one metal plate. It also helps to eliminate the possibility of intake manifold leaks causing oil consumption.

All in all, the LS1 was a revolution for GM, but it was also just another generation of the small block. And again, it was cause for concern off the bat since their main competitor, Ford, switched to overhead cams. But, as we now know, the cam-in-block design was more than good enough for the modern age.

7.0L LS7

Speaking of that 4″ stroke capability, that’s exactly how Chevy was able to develop the nastiest LS of them all, the 7.0L LS7. Functionally, it’s actually very similar to just about any Gen IV small block, which is also very similar to any Gen III small block.

But it’s not like Chevy just gave it massive displacement and left it alone. This engine was designed as something truly special.

By using that massive four-inch stroke combined with an even larger 4.125″ bore thanks to the pressed-in steel cylinder liners, they were able to create that giant displacement, but with the application being a high-performance variant of the Corvette, they also needed to ensure oiling wouldn’t become an issue, which is why they added a dry-sump oiling system that helps ensure adequate oil pressure during high-load cornering.

Unlike the other mass-produced LS, LQ, and LM engines, each LS7 was assembled by hand by a single builder at GM’s Performance Build Center in Wixom, Michigan.

This allowed them to follow all of the best low-volume production practices to ensure the best possible quality for this behemoth of an engine.

Other cool features of the LS7 include the doweled-in-place forged steel main bearing caps, forged steel crankshaft, precision deck plate honing, titanium connecting rods for reduced rotating assembly weight, higher flowing cylinder heads, an 11:1 compression ratio, a unique intake manifold to match the improved heads, and so much more.

All of this turned out a very impressive 505hp. And I know what the JDM guys are thinking. Hardy har har, your giant 7.0L only makes 500hp, and my modded 2.0L makes that much. Listen, one, no one cares, and two, the LS7 makes gobs of torque, is super reliable, and can easily be bumped to over 600hp with minor modifications.

Honestly, we could keep going on and on and on about different LS engines and how they had profound impacts on the automotive market. From the LS9 and LSA to the LS3 and even Chevy Performance LSX motors. The point here is that the LS engine has dominated the world of drag racing performance, road racing, drifting, and much more.

It’s relatively affordable, very easy to swap around parts, very easy to get safe power out of naturally aspirated, it’s incredibly compact for the displacement options, and so much more.

But, enough of the LS, now let’s look at the next engine on the list, the Gen V small-block, also known as the LT.

Gen V LT

Like the LS engine it was replacing, the LT features an all-aluminum design, coil near-plug ignition, and loads of other similarities. That being said, the biggest and arguably the most important difference with the LT is the change to direct injection.

The LT V8 engine family includes the LT1, LT2, LT4, LT5, L83, L86, L8T, and a few others. All of these engines feature the previously mentioned direct injection fuel system, variable valve timing, active fuel management, electronic throttle control, and other advanced features.

I think it’s worth briefly noting that of all those engines, the L8T is the only engine that uses an iron block but is otherwise the same as other LT engines.

Cast-in-place cylinder liners result in an all-aluminum deck face with induction liner heating utilized for dimensional control. This results in the exact placing of every cylinder in every block. Nodular iron main caps, retained with six cross-bolts, replace previous main caps where powder metal is used.

In addition to the redesigned main caps, every cylinder features oil-spray piston cooling, where eight oil-spraying jets in the block drench the underside of each piston and the surrounding cylinder wall with an extra layer of oil to further reduce in-cylinder temperatures and improve lubrication.

One of the major additions to the Gen V comes on the camshaft, which now features a variable valve timing control mechanism on the front of the cam, while at the rear of the cam, using lobes to drive the mechanical fuel pump for the direct injection system.

This new variable valve timing offers an enormous swing of over 60 degrees of authority over the camshaft position, which ultimately means a much wider power band, improved peak power band, and much-improved fuel efficiency.

For the intake manifold, GM used an all-new design, allowing air to get to the combustion chamber easier. More impressively, the imbalance of airflow is reduced by 50% compared to the outgoing small block.

All in all, the LT is a lot like the previous Gen IV and Gen III engines while also massively improved on a bunch of fronts for improved power and efficiency without switching to an overhead cam design.

And while I praise GM for pushing the limits of what is possible with a cam-in-block design, ultimately, overhead cam engines are superior, which takes us to GM’s newest performance engine, the LT6.

C8 Z06 LT6

And what makes this newest engine so interesting, so special, is that it’s a departure from the same cam-in-block design that Chevy has been using for so many decades now.

And for this engine, Chevy had a lot of hurdles to clear and big aspirations for what it was capable of.

Really, this engine started as the LT6.R racing engine. In fact, the racing division worked closely with the small-block production team to co-develop both engines, with both groups sharing data, ideas, issues, and so on.

What’s even more interesting is that both engines share cylinder block, heads, valvetrain, and fuel system designs. Meaning the LT6 is mostly a straight-up racing engine with minor changes for emissions systems and reliability. But, because the production LT6 isn’t a racing engine, it’s not held back by restrictions like the race team is, meaning the LT6 makes even more power than the LT6.R engine.

How much power, you might be asking? The answer is 670hp at 8,400rpm and 460 lb-ft at 6,300rpm. Right off the bat, you might be thinking, cool, the LT4 makes around that power, and Hellcats make a little more, so what’s so special here? Unlike just about any other engine around this power, the LT6 is naturally aspirated and not super or turbocharged.

On top of that, it’s not like it has some sort of massive displacement like the 7.0L LS7. Nope, it’s only a 5.5-liter engine. Getting that kind of power out of a 5.5L V8 without the use of race gas, ethanol, forced induction, or a hybrid drivetrain is flat-out insane.

And for them to get to that kind of power, it wasn’t easy.

Starting with the two most important factors that allowed them to push out that kind of power, we have the insanely well-designed cylinder heads and flat-plane crankshaft design.

Starting with the heads, we have a dual-overhead-cam design. The two cams per bank of the engine are then controlled by dual independent hydraulic camshaft phasing, with the intake side at 55 degrees of authority and the exhaust side at 27 degrees of authority.

The even weirder part of the heads? There are no hydraulic lifters!

You might be wondering why, and it’s simply because hydro lifters simply don’t like high RPM usage, and this engine was designed with that in mind. Instead, it uses a mechanical system that uses robotically-installed steel lash caps that require no zero maintenance.

Of course, with the high RPM demands and high power demands, the cylinder heads need to flow a lot of air.

You need air to add fuel and to make power, and this is again where we see massive improvements, with the LT6 heads even beating out the famed LS7 heads in terms of airflow. It’s flat-out ridiculous how much airflow these heads have.

On the bottom end of the engine is the other incredibly important part of the LT6 engine, and that’s the flat-plane crankshaft. We’ve discussed this in other articles, but there are both benefits and drawbacks to this type of crankshaft compared to the standard cross-plane crankshaft we’ve seen in other GM V8 engines.

One of the biggest benefits is weight, with the forged-steel LT6 crankshaft coming in 33% lighter than the crank in the LT2, which is the standard C8 Corvette engine. With less weight comes the ability to rev the engine up and down much faster and also better survive high RPM conditions.

The downside is that flatplane cranks tend to cause significantly more vibration, which is why Chevy settled on the 5.5L of displacement, as it’s very hard to go any larger than that while keeping the engine from rattling apart.

The rest of the rotating assembly is also very lightweight, featuring titanium connecting rods and forged pistons, both of which are lighter than any other GM V8 engine. This further improves the ability to rev the engine up quickly and also survive high RPM use.

And the part that houses everything, the cylinder block, well, that also has some interesting innovations. More specifically, the LT6 is a two-piece block consisting of the block casting and an aluminum lower crankcase casting (LCC).

Both the block and LCC are partially machined, leak-tested, flow tested, then bolted together, finish-machined, and serialized as a matched set. Once that happens, they are together forever. Just as with a race engine, the block is bored and honed using a deck plate.

Combine all that with other innovations of the LT6 like the ridiculous dry-sump oiling system, hot-side upside-down injectors, active intake manifold, dual throttle bodies, ridiculously lightweight and high-flowing exhaust, as well as loads of other innovations, and you can start to see how the LT6 is without a doubt, Chevy’s best and most complicated V8 engine ever.

And the proof is in the numbers. It’s the most powerful, naturally aspirated production ever. It’s almost the exact same weight as the LT2 while producing an extra 175hp and so much more.

Summary

For now, though, that’s that. We’ll have to wait to see what Chevy conjures up for the ZR1, and as time moves on, we’ll likely see them introduce turbocharged or hybrid V8 engines in the near future.

From 1917 to now 2023, Chevy has made a lot of engines throughout the decades. Most of them are good, some of them bad, and some of them outright insane.

Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this website.