Disappointed on the results of their performance in three straight years, Mazda finally came to a realization that they must up their game for them to compete against the European and other engine powerhouses. This does not come easy as they faced different struggles along the way, some of which are not achievable in the shortest amount of time.

But in 1991, they finally broke the chains, touching the evasive 700H P which they were aiming for and can last the challenge. The engine 13B motorsport was modified and resulted in the emergence of the 26B engine.

One of the most famous and sought-after internal combustion engine in motorsports, are those utilized by Mazda. The 26B rotary was a staple during their time at LeMans with drivers taking home victory behind its powerplant while driving the 767 back in 1991.

Let’s see how the development and innovation of this engine leads to the Mazda motorsport success.

What are Mazda 26B Rotary Engines?

A little bit of history, to the racing rotary engines of Mazda.

The first four-rotor engine, the 13J, was created in a short period of time, and despite its simple construction, its power output did not approach 600 HP. Furthermore, while being a lightweight and compact package was thought to be a RE’s ultimate strength, the 13J engine was lengthy and hefty.

Nonetheless, the front length of the engine was substantially decreased within a few months, and a lighter, better 13J engine was built. However, the hurried development had its toll, and in 1988, the newly designed Mazda 767s with their four-rotor engines experienced several issues and dropped well behind in the race, finishing 17th and 19th overall.

With that, Mazda opted to create the 26B, Mazda’s most notable 4-rotor engine. It was only utilized in different Mazda-built sports prototype vehicles, notably the 767 and 787B, to replace the previous 13J.

The Mazda 787B powered by a 26B engine became the first Japanese vehicle and the first car powered by anything other than a reciprocating piston engine to win the 24 Hours of Le Mans event outright in 1991.

The 1991 engine included a linear variable air intake system, which allowed for more fine-tuned control than the 1990 model. An actuator that expanded and retracted the length of the intake air horn was connected to the throttle. At low speeds, the longer the horn, the thicker the torque, whereas at higher speeds, the shorter the horn, the more power available.

Prior to the event, a 24-hour endurance test was undertaken, and in 1991, the team proceeded to Le Mans with a complete system in place, eventually winning the legendary 24-hour race overall.

After making all of the necessary changes to the car’s body, a vehicle capable of competing with European powerhouses like as Mercedes, Jaguar, Porsche, and Peugeot was completed.

Engine Specifications and Design:

- Production Run: 1991

- Configuration: Rotary

- Displacement: 2.6 L (2616 cc) 654 cc x 4 rotors

- Compression Ratio: 9.0

- Weight: 320 lbs.

- Maximum HP: 700 HP at 9,000 RPM

- Maximum Torque: 450 lb-ft at 6,500 RPM

Engine Design:

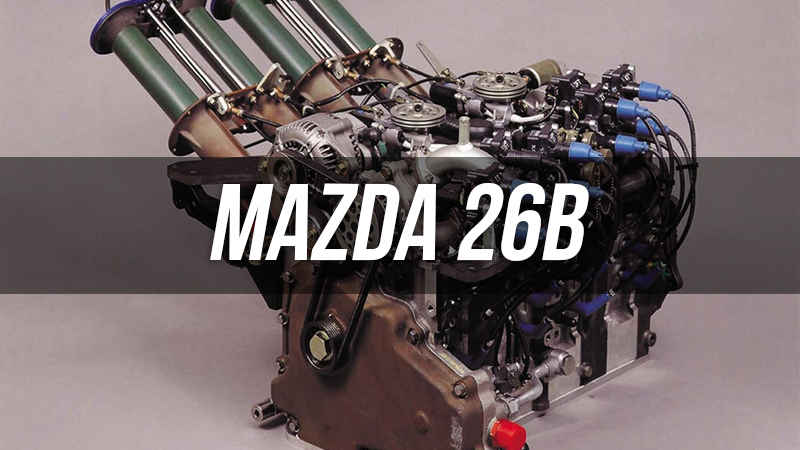

The 26B engine displaced 2.6 L per set of four chambers (counting just one 654 cc chamber for each of the four rotors) and produced 700 horsepower at 9000 rpm (thus the “26” in the series designation). The engine design has peripheral intake ports, continuously changing geometry intakes, and a third spark plug per rotor.

The R26B was lighter, smaller, and more cost effective than its processor. The variable intake system on the R26B Wankel engine optimized air intake for different vehicle speeds. Ahead of the rear wing, two periscope-shaped air intakes were installed.

Each intake assembly was connected to a telescoping-pulley system that allowed the height of the projecting periscopes to be adjusted over a six-inch stroke. The ECU computer in the automobile controlled the expansion and retraction of the intakes based on vehicle speed.

That significant discrepancy just emphasizes how much the rotary needs assistance with low-end torque. That is a really lengthy ingestion. The science behind it is fascinating.

The goal of a properly tuned intake runner is to provide “resonance supercharging,” which means that the air drawn into the engine through the intake pulls all the way down in a pressure wave, compressing itself up against the intake opening up at just the right time and at just the right engine speed.

At high speeds, the intakes were retracted to minimize drag and smooth airflow over the rear wing, as well as to lessen air flow constraints into the engine.

The intakes were expanded at lower speeds to offer maximum positive pressure to the charge entering the rotors. It also included an additional spark plug on each rotor, as opposed to the 767’s two, making the automobile more efficient and boosting combustion.

An oil cooler was installed in the front, and the aerodynamics of the car were enhanced on the sides and top of the bodywork. It, like all prior engines, used Peripheral Porting to create high levels of power from a normally aspirated engine.

Engine revolutions per minute (RPMs) were purposefully maintained low to ensure lifespan under the intense strains of a 24-hour endurance race. The redline of the 787 was said to be about 9000rpm.

However, conversations with Mazda’s 787 racing engineers indicated that the quad-power rotor’s grew significantly over 9000rpm. According to one expert, the automobile might produce more than 930hp and have a redline of roughly 10,500rpm.

Engineers further stated that during the post-race examination and tear-down of the quad-rotor engine, they discovered that all components of the engine were still in outstanding shape and that it could have ran another 24-hour race.

Applications of Mazda R26B Engine:

- Mazda 787

- Mazda 787B

Engine Potential:

The 4-Rotor 26B is the pinnacle of Mazda performance, with neck-snapping horsepower and torque that will take your breath away.

The unique 4-rotor engine is one of the most technically complex rotary engines ever created. From start to finish, each element is meticulously machined to the closest specifications and hand-assembled with precise detailing. The horsepower potential mentioned is an average tuned result. Depending on the individual’s expertise in n/a tuning, much more can be generated.

For the tallest primary ports, 12a side housings are used; all side housings are refurbished and re-nitrated for a fresh new finish. Complete the street port to “circuit” specifications. 9.7 rotors with new side seals, corner seals, oil retention rings, oil o-rings, coolant o-rings, and springs High-quality 2-mm apex seals with brand-new springs. New rotor housings portBd to “race” port exhaust.

In this build, you can reach 900 HP in turbocharging.

However, there’s another way to do it. This can result in a 1,200 HP build though so better watch out.

This is the most common 26B build. This unit is both durable and cost effective, and it can be used non-turbo or turbo with good results. This engine may be built in a variety of configurations, including streetport, bridgeport, and semi-p-port.

Late type 13B side housings are used, and all side housings have been refurbished and re-nitrated for a fresh new finish. 9.0:1 rotors with new side seals, corner seals, oil retention rings, oil o-rings, coolant o-rings, and springs High-quality 2mm apex seals with brand-new springs. New rotor housings that have been machined and equipped with a complete peripheral port, “race” port exhaust.

Problems Surrounding Mazda 26B Rotary

It’s no secret that rotary engines require a lot more maintenance and care than ordinary piston engines.

As a result, they aren’t everyone’s first choice, but those who are ready to put in the time and effort will be rewarded with one of the most extraordinary engines ever built.

After spending far too much time looking for your 26B, because they are pretty rare, the first thing that should spring to mind is what type of life this engine has had. Because of its antiquity, you’ll want to conduct a thorough check for any evidence of neglect or misuse to avoid damaging such an unique piece of engineering.

If you find one and suspect it’s had a tough life, but there’s no history to back it up, we’d advocate rebuilding it.

New apex seals and seal springs, side seals, side seal springs, inner and outer o-ring seals, and new gaskets are all possible.

Given the nature of rotary engines, we recommend hiring a reputable company to complete a rebuild rather than attempting to do the work yourself. It will surely be beneficial, particularly when it comes to selling.

Summary

The manner Mazda won the overall championship in 1991 was as much a quirk of the regulations as anything else, but the triumph was a proof of concept for the rotary, and an extraordinary tech demonstration for what now appears to be an engineering dead end.

Perhaps that’s why the engines left a big legacy to live on and many people and enthusiasts enjoy it so much: it seems like a fragment of a Bladerunner parallel history crashing into our reality and screaming its lungs out.