You’ve just heard about stroker motors for the first time, but you are confused as to what they are. I’ll be glad to tell you exactly what a stroker motor is and how it works.

Well, good news: you’re not alone. At some point, everyone had to learn what a stroker motor is, and there is no shame in not knowing something.

Before I can dive into how a stroker motor works and why you’d want one, I first need to explain how an engine works.

How an Engine Works

The standard internal combustion engine works by taking linear force and turning it into rotational force through a rotating assembly (crankshaft).

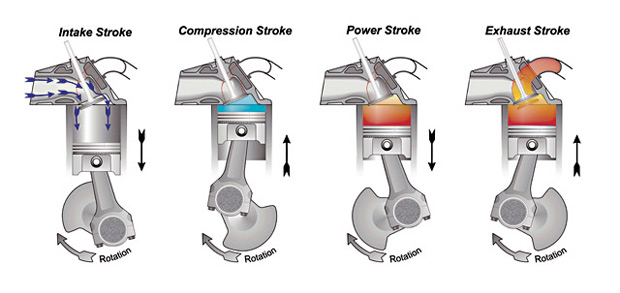

The cylinder size is measured by width (bore) and height (stroke), and that gives it its overall displacement. The piston moves up and down through a 4-stroke process.

Intake, compression, combustion, and exhaust, are the steps. The combustion forces the pistons downwards, which is transferred into rotational force through the crankshaft. That rotational force is what drives your car forwards.

This design has been around for a very long time and is unfortunately very inefficient. Many small companies have developed much better internal combustion engines, such as the Duke engine.

However, manufacturers have the standard internal combustion engine to the point that it wouldn’t be cost effective to develop a better combustion engine.

How to Increase Stroke

Stroke can be increased in some engines with a “stroker” kit. Many aftermarket companies make stroker kits for various kinds of engines.

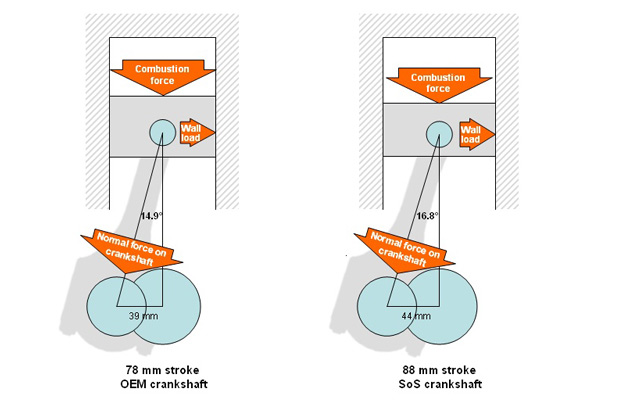

The kit will increase the stroke by increasing the length of the crankshaft throw and decreasing the length of the connecting rod.

This makes the piston move down further while keeping its peak height the same as the factory engine.

Why do you need to keep the height of the stroke the same as stock? Well, if you didn’t, the piston would force itself the cylinder head, and your engine wouldn’t work at all.

You can also decrease stroke with the opposite method. Decreasing crankshaft throw and increasing connecting rod length will de-stroke an engine, which might be handy if you need your engine to be smaller to fit into certain classes of racing.

For example, the Honda B16B is a de-stroked version of the Honda B18C5.

What is Torque?

Ask yourself, what is torque? Torque is a rotational force and is measured by lb-ft in America and some other parts of the world.L

et’s say you weigh 170lbs, and you are trying to get a lug nut off of your car. The wrench you are using is one foot long. If you put your entire body weight on the end of that wrench, you would be applying 170 lb-ft of torque on that lug nut.

Maybe the lug nut is stuck on, so you bust out your breaker bar. Now the wrench is effectively 3 feet long, and you put your entire body weight on the end of the breaker bar.

Now you are applying 510 lb-ft of torque to that lug nut (3×170=510).

If Torque is Rotational Force, Then What is Horsepower?

This is an excellent question, and it can be confusing if you don’t already understand the difference. Horsepower = (Torque X RPM)/5252.

Say you’re applying 100 lb-ft of force on something, and you’re turning it 100 times per minute. You would effectively be making 1.9 horsepower.

Now let’s say you’re doing the same thing, but you’re turning it 500 times per minutes. Now you would effectively be making 9.5 horsepower. Think of it like this: Torque is how hard the engine is working, horsepower is how much the engine is working.

That is the easiest way to explain what rotational force and horsepower are and how they are measured. If you do not quite understand this concept, I recommend watching educational YouTube videos for more information.

Why Increase Stroke?

A small stroke allows the engine to rev higher, and thus make more horsepower, so why would you want to increase the stroke? Well, horsepower isn’t everything.

Increasing the stroke increases the torque an engine can make. Torque is a rotational force, and it propels your car forwards.

The torque rating is what matters when you are just cruising around town. If your vehicle has a tremendous amount of torque, you don’t have to rev it up very high to accelerate quickly.

Why is that a good thing? Well, let’s assume you’re on the highway in 5th gear. If your vehicle doesn’t make lots of torque, you will have to downshift to pass the person in front of you, if your vehicle does make a lot of torque than you won’t need to downshift to pass the car in front of you.

For drag racers and street racers, this is great, as it allows them to get out of the hole quicker. For road racers, torque is a little bit less important since they are often high up in the RPMs where the engine makes its peak horsepower.

How Does It Increase Torque?

Well, remember when I was explaining how torque is measured? It’s like taking a lug nut off. Since increasing the stroke is done through increasing the crankshaft throw, adding a breaker bar to your lug nut wrench would achieve the same effect.

The combustion inside the cylinder has more leverage on the crankshaft, thus creating more rotational force, and creating more torque.

Words can be difficult to understand, so I urge you to watch the video below to better understand how a stroker motor works.

Common Stroker Motors

The most common size stroker motor varies from engine to engine. I will briefly cover the most common stroker engine size for Ford and Chevy.

Small block Ford engines that came in Fox Body Mustangs are typically stroked from 302ci to 331ci or 347ci.

The larger 351W that can be swapped in can be stroked to all the way up to a 408ci or larger depending on the cylinder block. The 4.6L modular Ford engines are stroked to 5.0L, 5.2L, or 5.4L.

Small block Chevy engines are typically stroked from 350ci to 383ci. Different Chevy blocks are stroked to different sizes; some are even de-stroked.

Back in the day racers use to stroke 400ci engines down to 377ci to allow for high revs and more power. LS1 engines can be stroked to 383ci, and larger LS engines like the LS3 can be stroked up to 427ci.

Summary

To summarize, just remember that a stroker motor is a standard engine, but with an increased stroke in the cylinder.

This increases total displacement resulting in more torque and more horsepower. These motors are often used in muscle cars, as they give it that muscle feeling.

If you don’t have to rev your car out to beat somebody else, it feels pretty awesome. Of course, stroking or de-stroking an engine isn’t just limited to muscle cars.

It is very common in the tuner world.

Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this website.

In my endeavors to be knowledgeable. I would like to go to a parts yard look for the multiple pieces for the inches I want to build. Machines those parts as needed, and bypass every stroker that finds a place in my pocket. Its a lot of money to have the desire, and watch your hard earned cash supply another racers corner. And for the info I do find here and what I can use and understand. Im hoping for some kind of success.

well first time ever i have really understood what this stroker and torque is all about. I know this is an older article but it is the simplest I have come acros that gave me the oh i get it moment. thank you