In the off-road community, engine swaps can be a touchy subject. Most of the time, torque is what you’re looking for, as that’s what will allow you to turn big tires at low RPMs. Of course, there are plenty of horribly underpowered trucks that do just fine with extreme gear ratios.

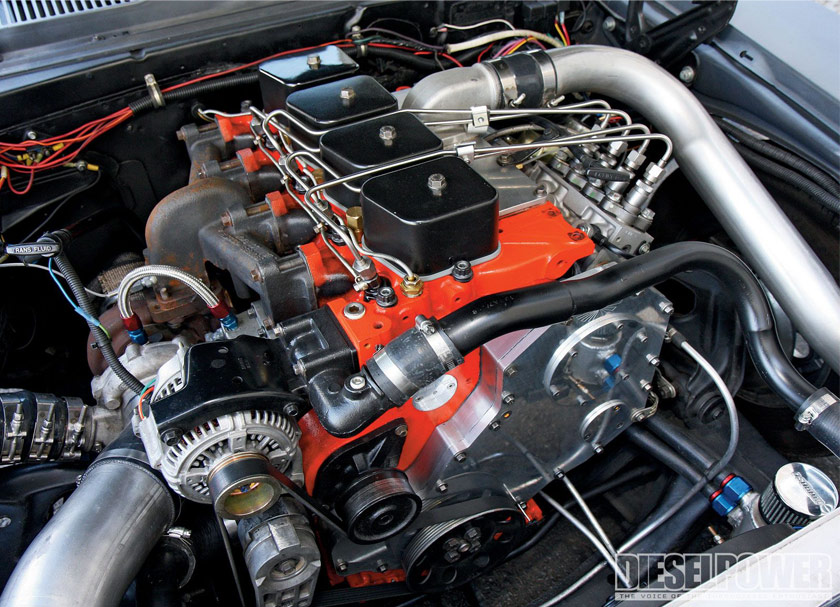

Because of that, Chevrolet LS engines are pretty common, especially the truck version of the LS family. But diesel engines, specifically the 4BT Cummins, are becoming increasingly popular, and for good reason.

It’s not just off-roaders who are using this engine. It can also be found in everything from 240SX drift cars to Mustang drag cars, although it’s not a great swap for streetcars due to its hefty overall weight and low power figures.

Before I tell you everything you need to know about this engine, I must first inform you of the absolute basics of the 4BT. You can find even more 4BT information on Wikipedia.

4BT Cummins: Engine Basics

In the world of “light-duty” trucks, the 6BT Cummins, also known as the 12-valve Cummins, is legendary. Think of the 4BT engine as a shrunken-down version of the 6BT engine. Nearly all of its architectural and internal designs are shared with the 6BT.

The large size of the 6BT meant that it couldn’t fit in vehicles or equipment where there wasn’t a massive amount of space which is where the 4BT Cummins comes into play. The 4BT shares most of its components with the 6BT but with two cylinders missing.

The pistons, injectors, connecting rods, and valvetrain design are straight off of the 12v Cummins. The crankshaft and cylinder head are different, as there are two fewer cylinders on the 4BT compared to the 6BT. Even though the 4BT is significantly shorter than the 6BT, it’s still a large engine, especially for a four-cylinder.

- Displacement: 3.9L – 292ci

- Bore: 4.02″

- Stroke: 4.72″

- Configuration: Inline Four-Cylinder

- Deck: Closed Deck

- Weight: 750+ lbs

- Cylinder Head Material: Cast Iron

- Engine Block Material: Cast Iron

- Compression Ratio: 17.5:1

- Valvetrain: OHV – 2 Valves per Cylinder

- Horsepower: 105hp (4BT) – 170hp (4BTA)

- Torque: 265lb-ft (4BT) – 420lb-ft (4BTA)

Out of the units listed above, weight is the most surprising. While most four-cylinder weigh around 400-600 lbs, the 4BT weighs a hefty 750+ lbs (the exact number depends on engine dressings and fluid level.)

Horsepower may seem relatively low, especially for a 3.9L engine, but you must remember that the 4BT was designed for low-end torque and superb reliability. The post-1998 version, 4BTA, had a significant power bump thanks to its jump from eight to sixteen valves. The 4BTA upgrade is similar to the change on the 6BT, where the valve count was increased from 12 valves to 24 valves.

4BT Cummins: Real World Applications

Thanks to its size, power output, and mechanical fuel injection system, the 4BT can be found in a plethora of different applications. It’s not uncommon to see this engine in industrial equipment. The most common place you’ll find a 4BT is in bread trucks.

Bread trucks are large trucks that may have a relatively heavy payload but have a tiny engine bay, making the 4BT the obvious choice. That being said, it’s not a “small” engine as compared to a gas four-cylinder, but it’s still very small compared to larger diesel engines like the 6BT. There is not any official list of 4BT applications, but bread trucks are definitely the most common application.

Modern applications have since moved on to newer and more efficient diesel engines, including the R2.8 Cummins.

4BT Cummins: Tuning Potential

The 4BT is by no means a performance engine. As we said above, it was used in applications such as bread trucks, and the numbers show it. Outputting a measly 105 horsepower @ 2,300 RPM and 265 lb-ft @ 1,600 RPM, it’s far from a screamer.

Of course, the 6BT is also very weak straight from the factory, but with some modifications to the fuel system and fuel timing, big power can easily be achieved. The common 6BT fuel modifications apply to the 4BT, as they share the same fuel pump and injectors.

If you want big horsepower, a turbocharger upgrade is a great place to start. An HX35, HE341, or HE351 are great budget options that will flow significantly more air than the stock 4BT turbocharger at the cost of throttle response.

All 4BT applications lack an intercooler which is great for packaging constraints but terrible for power. An intercooler is a great way to pick up horsepower and improve power consistency by keeping charge air temperatures lower.

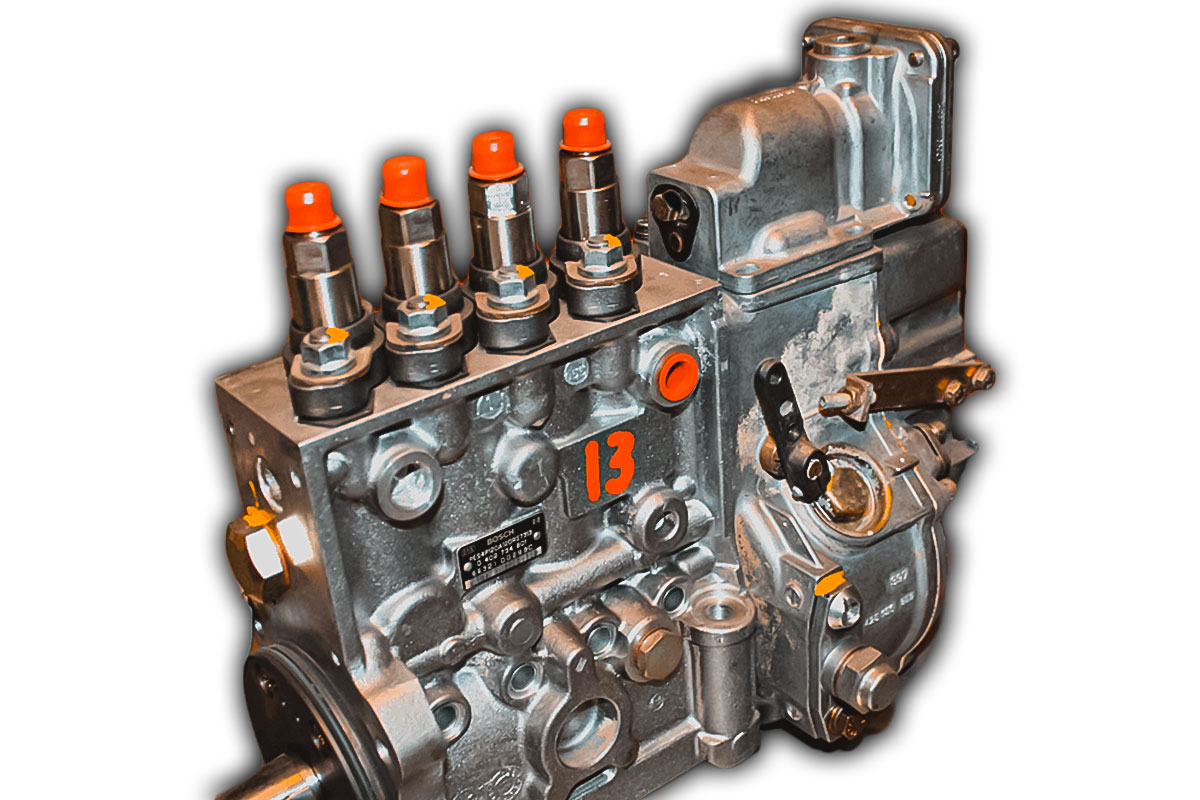

As far as fueling is concerned, upgraded injectors are an excellent place to start but are not necessary for small power increases. The P7100 fuel injection pump is the same one found in the 6BT.

Sliding the Air Fuel Control assembly forward will result in power gains by adding fuel at low RPM. You can also ground down or remove the fuel plate which is what controls the maximum fueling.

By sliding the AFC assembly forward and grounding down the fuel plate, you can see gains up to 100hp and 200+ ft-lbs. Fuel timing is crucial on the 4BT, so be sure to set it right, or you may have a blown engine on your hands.

Past the basic fueling mods, aftermarket governor springs are a great way to pick up power. The OEM governor springs of the P7100 pump limit the engine to 2,700rpm, with de-fueling starting at 2,400rpm.

Aftermarket governor springs will allow full fueling up to 3,000rpm or even 4,000rpm, depending on what spring kit you purchase. It should be noted that four-cylinder engines are not as inherently balanced as six-cylinder engines, so don’t expect to rev a modified 4BT engine as high as a modified 6BT engine.

Tuning potential depends entirely upon budget, but it’s not too hard to get a 4BT up to 300 horsepower and 700lb-ft. It should be noted that the fueling modifications listed above apply only to 4BT engines with the Bosch P7100 pump.

Models with the later VE pump require different modifications. Check out DrivingLine’s P-Pump Cummins fuel modifications for more detailed information.

4BT Cummins: Why Swap?

So from everything I’ve told you so far, why would you want to swap a 4BT into your vehicle? If you’re able to fit a 6BT 12 valve into your vehicle, then that is probably the way better option. It’ll make more power, last just as long, and might be cheaper to buy.

The real reason you might want to swap a 4BT is for fuel mileage and size constants. A 4BT barely fits into an XJ Cherokee with a 6″+ lift, so a 6BT is definitely out of the question for many Jeep owners. If fuel mileage is your legitimate reason for swapping, then the 1.9 TDI from VW is a far better option.

Highlights of the 4BT Cummins:

Cummins engines, manufactured by Cummins Inc., an American Fortune 500 corporation, have been an integral part of the automotive industry for many decades. Known for their durability, power, and reliability, Cummins engines are widely revered among truck owners and auto enthusiasts. Here are the key factors that make Cummins engines stand out.

1. Unparalleled Durability

Cummins engines are renowned for their longevity and durability. They are designed to withstand rigorous conditions and extreme use, making them a favorite among heavy-duty truck owners. The engines often surpass the lifespan of the vehicles they power, demonstrating their inherent resilience.

2. Exceptional Performance

The performance of Cummins engines, particularly in the heavy-duty truck segment, is second to none. They are celebrated for their impressive torque and horsepower figures, allowing them to comfortably handle heavy loads. The high-displacement design further improves low-end torque, making these engines ideal for towing and hauling applications.

3. Fuel Efficiency

Despite their power, Cummins engines are recognized for their excellent fuel efficiency. Through continuous innovation and technological advancements, Cummins Inc. has managed to balance performance and economy, making their engines cost-effective for both commercial and personal use.

4. Aftermarket Support and Availability of Parts

Another major advantage of Cummins engines is the wide availability of aftermarket parts and support. This allows owners to customize and enhance their engines based on their specific needs. Additionally, the extensive availability of replacement parts makes maintenance and repairs relatively straightforward and affordable.

5. Low Maintenance and Easy Repairs

Cummins engines are engineered with simplicity in mind, which makes them easy to work on. They require less frequent service intervals compared to other engines, reducing overall maintenance costs. When repairs are needed, their widespread use and straightforward design make it easier for mechanics to diagnose and fix problems.

Summary

So what have we learned so far? The 4BT came in heavy-duty applications such as bread trucks, it’s nearly identical to the 12-valve, it responds to modifications just like a 12-valve, and it’s incredibly reliable. Many 4BT engines have gone way past 300,000 miles.

Jeep people love the 4BT because it is pretty much the best diesel that can fit inside of a Jeep other than the much less common 1.9 TDI swap. Let me know what you think of the 4BT in the comments below! Also check out our 6BT Cummins: Everything You Need to Know article!

Disclosure: As an Amazon Associate, I earn from qualifying purchases made through links on this website.

I am looking for a 4bt for my

1947 power wagon .

What I’m curious about is the horsepower and torque ratings for the Cummins 4BT diesel. 105hp and 265lbs-ft torque doesn’t seem like much for an engine of 3.9 litres or for most apps.

Wondering what transmission work with

The bt4 swap I a tj

Bryce

Good morning and thanks for the articles. I want to swap a diesel in my 84 S10 extended cab. Can you suggest a diesel engine? the truck will be towed behind my diesel motor home, and rarely used as a work truck.

Thanks,

Harry

I bought a Cummins 4bt from Big Bear Engine company in January. I am now being told by others that I have a fake engine or a knock off. None of the engine numbers on the block are good supposedly. Suppose to start with 7 or 8. Mine starts with 1. Does anyone know anything definite about this?

What is the standard value of compression of 4BT engine?

I want to put a 4BT in my 2015 ford fiesta. Is this possible?

Why on earth would you do that?

I can think of a few reasons. Maybe just and excuse to do a RWD conversion and get rid of that GOD AWFUL CVT….lol

Great article. I have a 4BT 3.9M and just learned a lot. It’s a 1988 model and 8 valves. The boat i have is a 1978, 24 foot Eastporter trawler and only gets up to 11 knots. I just use it for fishing but am considering putting a 6bt in the boat and wonder how much longer it is. I think the weight of the 6bt is about 250 lbs heavier.

I’m looking to put a diesel in my ’59 M-37 Dodge power wagon. Is the Cummins 4BT the way to go? I would also like to change the gear ratio to get a bit more speed and less “screaming” from the rear. 40-45 mph is just a bit too slow. Top speed of 60-65 mph is what I’d like.

i am trying the same thing on my 1954 M37. Working with M-Series Rebuilds in North Carolina. seems there is a wait list for engines now… let me know if you did this project, and any lessons /advice?

wish alternator can I used on a cummins 4bt and the power steering pump.

I’ve installed 4 bt in a 1987 Chevrolet 1/2 ton and also in A 1994 Ford Super duty straight bed, 15;000 gvw. I used a beefed up 700r4 in the half ton with a 2.73 rear axle. I used a 5 speed ZF with a 3.73 in the straight bed. Low pressure pump in the 1/2 ton and high pressure pump on the staight bed. Lord fluid motor mount in both. 24-28 mpg in the half ton. 14-20mpg in the straight bed. No problems with either.

Would a 16v 4bt fit inside of my 4.0 ford ranger. Looking for a diesel for it that has capability of making decent power with mods.

Yes, look up the 4btswap forums theres a lot of good information on there regarding the 4bt swaps, also check out Ford Ranger Forums and The Ranger Station.. I myself am debating between building my 4.0 or diesel swapping for the power and fuel economy

I have a cummins 4bt out of a bread truck and I want to hook a 700r4 trans to it. what do I need to make it happen?

For an engine of this size, I would think that 170 bhp would’ve made a great starting point, and 425 ft.-lbs. of torque+ would’ve been a great starting point. 120bhp would’ve been fine for a car like the Dodge Diplomat or Plymouth Gran Fury, provided a suitable automatic gearbox could be mated to the Cummins Diesel engine.